3D-Printed Coral Reefs: Can We Engineer Marine Recovery?

TL;DR: A 10MW pilot plant in San Antonio proved supercritical CO₂ power cycles can transform captured carbon into electricity at 50% efficiency, potentially cutting 180 million metric tons of annual emissions by 2050.

By 2050, we'll need to slash greenhouse gas emissions by unprecedented amounts. But what if the carbon we capture doesn't just disappear into underground storage, what if it becomes the very thing that powers our homes? That's the promise of supercritical CO₂ power cycles, a technology that transforms captured carbon from waste into the beating heart of next‑generation electricity generation. In San Antonio, a 10‑megawatt pilot plant just proved this isn't science fiction anymore.

Carbon dioxide, heated beyond 31°C and pressurized above 73.8 bar, enters a strange fourth state of matter. It's not quite liquid, not quite gas. Scientists call it supercritical. In this state, CO₂ becomes an incredibly efficient working fluid for power generation, capable of spinning turbines at 27,000 RPM while achieving efficiencies that make conventional steam systems look like relics.

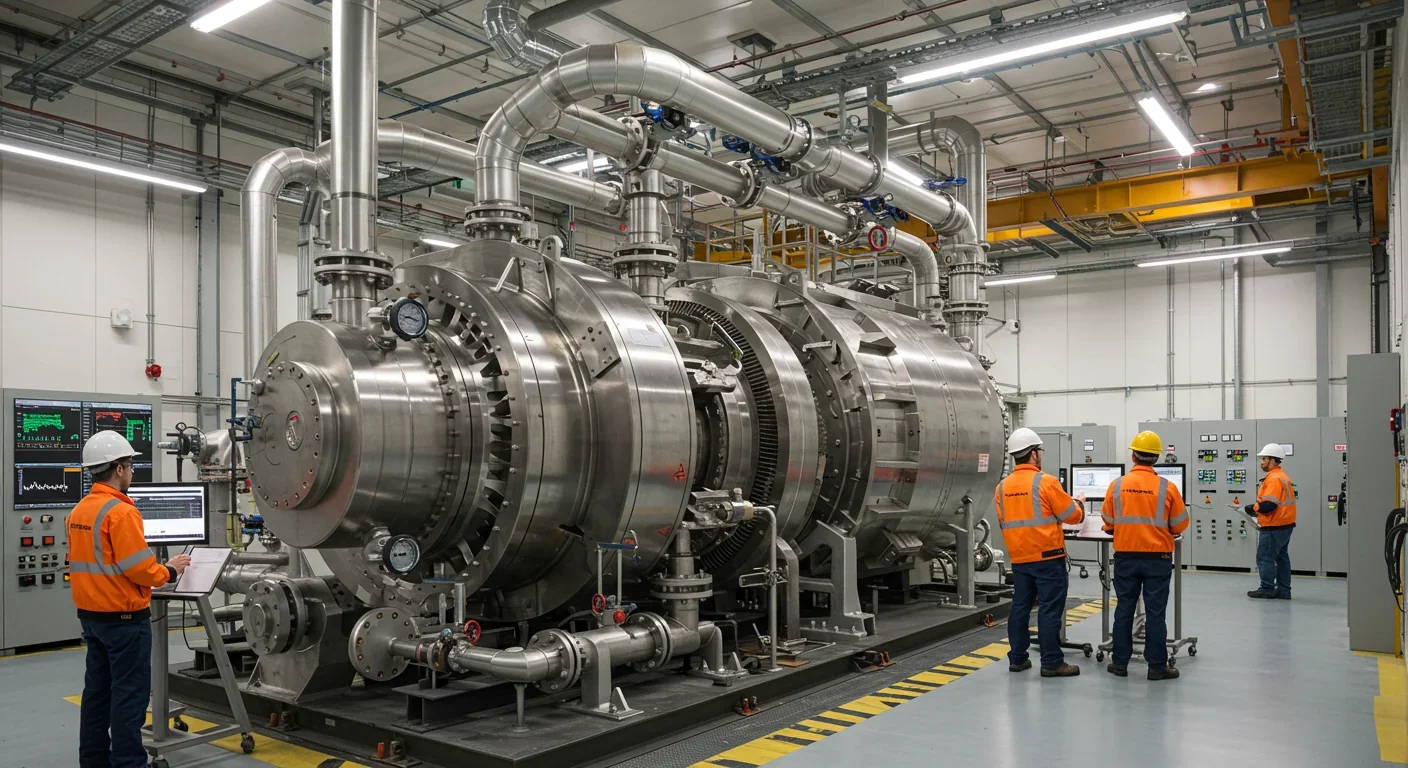

The STEP Demo pilot plant in Texas recently completed phase 1 testing, generating 4 megawatts of grid‑synchronized power at 500°C. That's enough electricity for 4,000 homes, produced by turbomachinery so compact it fits in a package 10 to 20 times smaller than an equivalent steam turbine. The turbine achieved the highest power density of any terrestrial turbine, delivering approximately 100 horsepower per pound.

But here's where it gets revolutionary. By using captured CO₂ directly as the working fluid, these systems turn carbon capture from an expensive necessity into a value‑generating asset. Every ton of CO₂ that would otherwise be sequestered underground can instead drive turbines, generate electricity, and earn revenue while still keeping carbon out of the atmosphere.

We've been using steam to generate electricity since the 1880s. The basic principle hasn't changed: heat water, create steam, spin a turbine, condense, repeat. It works, but subcritical steam plants top out around 39% efficiency, while advanced supercritical water plants only reach about 45%.

Steam requires massive turbines because water vapor has relatively low density. You need huge condensers, extensive cooling systems, and kilometers of piping. A typical steam turbine for a 10‑megawatt system would fill a warehouse.

Supercritical CO₂ changes everything. Because of its high fluid density, sCO₂ enables compact turbomachinery. The Brayton cycle using supercritical CO₂ can achieve theoretical efficiencies exceeding 50%. For concentrated solar power applications, researchers have benchmarked substantial efficiency improvements over conventional Rankine cycles.

What's different now is the combination of three factors: the urgent need for carbon capture, advances in high‑temperature materials, and CO₂'s unique properties at supercritical conditions.

Think of supercritical CO₂ as a closed‑loop heat engine on steroids. Captured CO₂ is compressed to pressures around 250 bar, then heated to temperatures exceeding 700°C using natural gas, concentrated solar, nuclear, geothermal, or waste heat.

At these extreme conditions, the sCO₂ expands through a turbine at incredibly high speeds. The STEP Demo's turbine operates at 27,000 RPM, generating up to 16 megawatts gross power. After expansion, the still‑hot CO₂ passes through heat exchangers called recuperators, where it preheats the incoming compressed CO₂. This heat recovery step pushes efficiency so high.

The devil is in the details. The STEP Demo uses Inconel 740H for high‑temperature components, a nickel‑based superalloy that can withstand 700°C temperatures and 250‑bar pressures. Manufacturing these components pushed the limits of welding and heat treatment technology. Early attempts at fabricating the 93‑megawatt thermal process heater encountered stress‑relaxation cracking, requiring new heat treatment protocols.

The turbine stop valve uses Haynes 282, another advanced superalloy. Some designs use supercritical CO₂ itself as the lubricant in hydrodynamic bearings, eliminating contamination concerns.

The STEP Demo didn't come cheap. This 10‑megawatt facility cost $169 million, funded through a public‑private partnership led by GTI Energy with the Department of Energy, Southwest Research Institute, and GE Research. That price tag reflects first‑of‑its‑kind engineering challenges.

But the investment is already paying dividends in knowledge. The pilot tests two configurations: a simple cycle targeting 500°C and a recompression Brayton cycle aiming for 715°C. Each provides operational data impossible to obtain through modeling alone.

The facility remains open for new partners to join the joint industry program, sharing costs and gaining access to deep technical insights. This collaborative model spreads risk while accelerating learning across the industry.

Other projects are moving forward globally. NET Power and California Resources Corporation are planning up to 1 gigawatt of carbon‑free gas power plants in California using the Allam‑Fetvedt cycle. Europe's sCO₂‑HeRo project has tested compressor designs for nuclear applications.

Concentrated solar power developers see sCO₂ as the key to cost competitiveness. Geothermal operators are interested because sCO₂ can efficiently convert lower‑temperature heat that would be uneconomical with steam cycles. Nuclear designers are exploring sCO₂‑cooled micro modular reactors for carbon‑free baseload power.

According to the Center for Climate and Energy Solutions, carbon capture could contribute up to 14% of the global greenhouse gas emissions reductions needed by 2050. Right now, most captured CO₂ goes straight to underground storage, an operating cost with no revenue stream.

Supercritical CO₂ power cycles flip that equation. Captured CO₂ becomes feedstock for electricity generation. The captured CO₂ can be repurposed into valuable products like chemicals, fuels, and building materials, creating new revenue streams.

In 2023, the announced capture capacity for 2030 increased by 35%, while announced storage capacity surged by 70%. That brings total potential CO₂ capture capacity to around 435 million tonnes per year by 2030. If even a fraction of that captured CO₂ flows through sCO₂ power cycles instead of direct storage, the impact on grid economics would be substantial.

Then there's the 45Q tax credit, preserved in the latest U.S. budget proposal. This federal incentive provides up to $85 per metric ton of CO₂ captured and stored. For a facility capturing millions of tons annually, those credits add up fast. Combined with electricity revenue from the sCO₂ power cycle, the economics start to look compelling.

One of the most intriguing aspects of sCO₂ technology is its flexibility. As GTI Energy's VP Don Stevenson notes, "The technology is incredibly versatile, whether it be in zero‑emission waste heat recovery, or coupled with concentrating solar, nuclear, biomass, geothermal, coal, or for long‑duration thermal storage."

This versatility means sCO₂ isn't locked into a single market. It can serve as a bridge technology, enabling utilities to keep reliable power production while gradually integrating renewable sources. Industrial facilities with high‑grade waste heat can retrofit sCO₂ bottoming cycles to boost efficiency. Renewable energy developers can use sCO₂ for thermal energy storage.

Material science remains a critical constraint. Operating at 700°C and 250 bar isn't forgiving. Inconel 740H and Haynes 282 are expensive and require specialized welding techniques. Research continues into new channel designs for heat exchangers that can handle the thermal stresses.

Dynamic characteristics of supercritical CO₂ recompression Brayton cycles differ substantially from conventional power plants. Response to load changes and emergency shutdowns require new approaches. The fluid properties of sCO₂ change dramatically near the critical point, making precise control essential but challenging.

Then there's the supply chain question. How many manufacturers can produce turbomachinery rated for these conditions? What's the learning curve for installation and maintenance crews? The answers will determine how fast deployment can scale.

Regulatory frameworks also need to catch up. Should sCO₂ power cycles be regulated like thermal plants or carbon capture facilities? How do you account for the dual benefit of carbon sequestration and electricity generation in emissions accounting?

The competition to commercialize sCO₂ technology spans continents. The U.S. Department of Energy has funded multiple demonstration projects beyond STEP. European researchers are advancing compressor and turbine designs through coordinated programs. Asia's interest centers on retrofitting existing coal plants with carbon capture and sCO₂ power cycles.

Deployment incentives differ significantly between the EU and U.S., with Europe emphasizing carbon pricing and the U.S. favoring tax credits. These policy differences create varied paths to market.

What happens in China may matter most. As the world's largest emitter and largest power generator, China's choices on sCO₂ technology will significantly impact global deployment trajectories. If Chinese manufacturers achieve economies of scale in turbomachinery production, costs could drop faster than current projections suggest.

Within the next decade, you'll likely see the first commercial‑scale sCO₂ power plants come online. They won't replace every steam turbine overnight, but they'll carve out niches where their advantages shine: new nuclear plants seeking compact designs, solar thermal facilities chasing higher efficiency, industrial sites with high‑grade waste heat, and carbon capture facilities needing to improve project economics.

For energy professionals, this means new skills to develop: thermodynamics of supercritical fluids, high‑temperature materials science, turbomachinery design for extreme conditions. If you're early in your career, specializing in sCO₂ systems could position you at the forefront of the energy transition.

For policymakers, the question is whether to actively support sCO₂ deployment through incentives and regulatory frameworks. sCO₂ technology could reduce carbon dioxide emissions by more than 180 million metric tons annually by 2050, accounting for 12% of current U.S. electric power generation emissions. That scale of impact suggests active support is warranted.

For investors, the risk‑reward calculation depends on timescale. First‑generation commercial plants face technological risks. But if sCO₂ delivers on its promises, the market could grow to hundreds of billions of dollars globally.

There's a profound irony in using the very substance we're trying to remove from the atmosphere as the key to cleaner electricity generation. But that paradox points to a deeper truth: we don't just need to eliminate emissions, we need to build systems that are more efficient, more economical, and more reliable than what they replace.

Supercritical CO₂ power cycles do exactly that. They take captured carbon and transform it from a waste disposal problem into a performance advantage. They enable higher efficiencies with smaller equipment. They can integrate multiple heat sources. They turn the economics of carbon capture from purely cost to partly revenue‑generating.

The STEP Demo's success demonstrates that the fundamental engineering challenges can be solved. Materials exist that can handle the conditions. Turbomachinery can operate reliably at these scales. The path from pilot to commercial deployment is clear, even if significant work remains.

What comes next depends on whether we recognize this technology's potential and commit the resources to realize it. The physics works. The engineering is maturing. The economics are improving. The climate imperative is undeniable. Supercritical CO₂ power cycles offer a way to turn our greatest waste product into our cleanest energy source. That's not just innovation. It's transformation.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

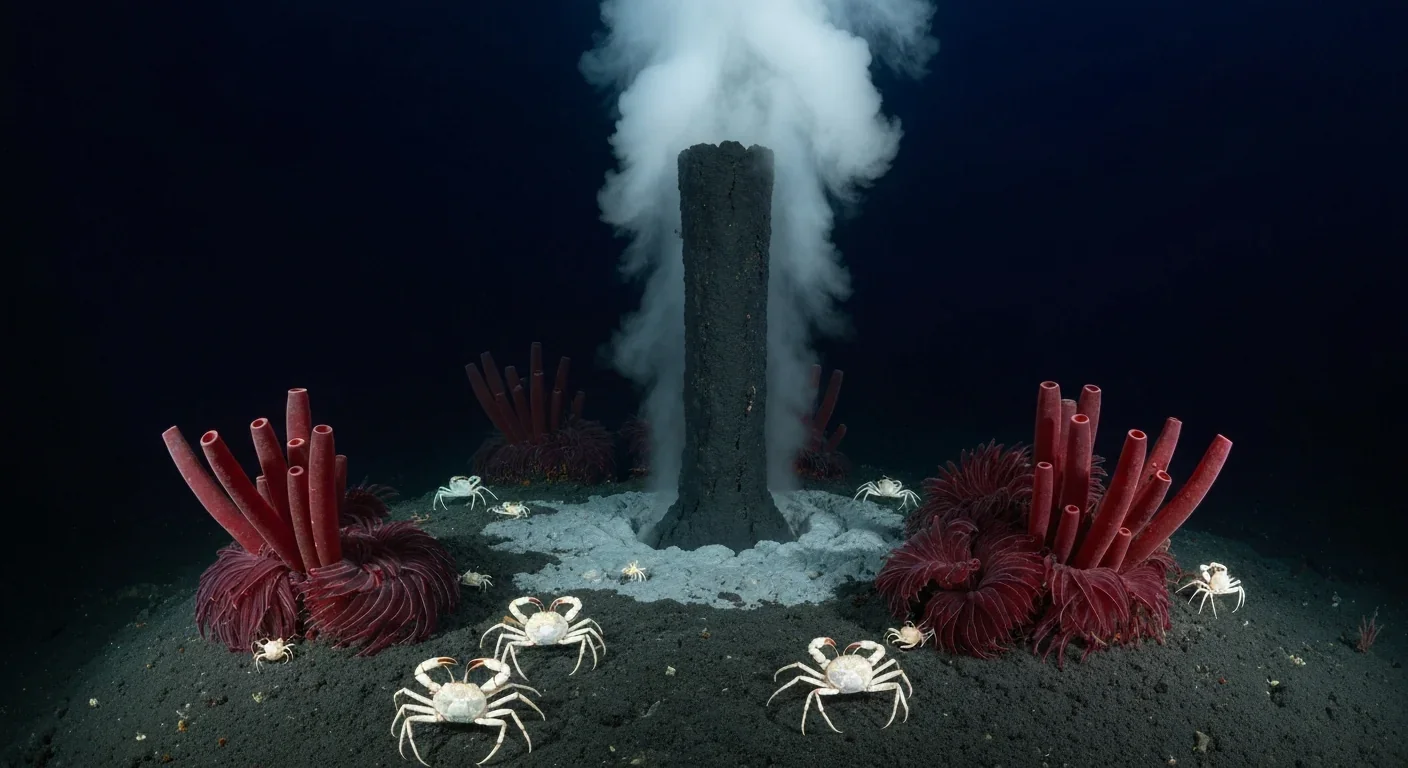

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

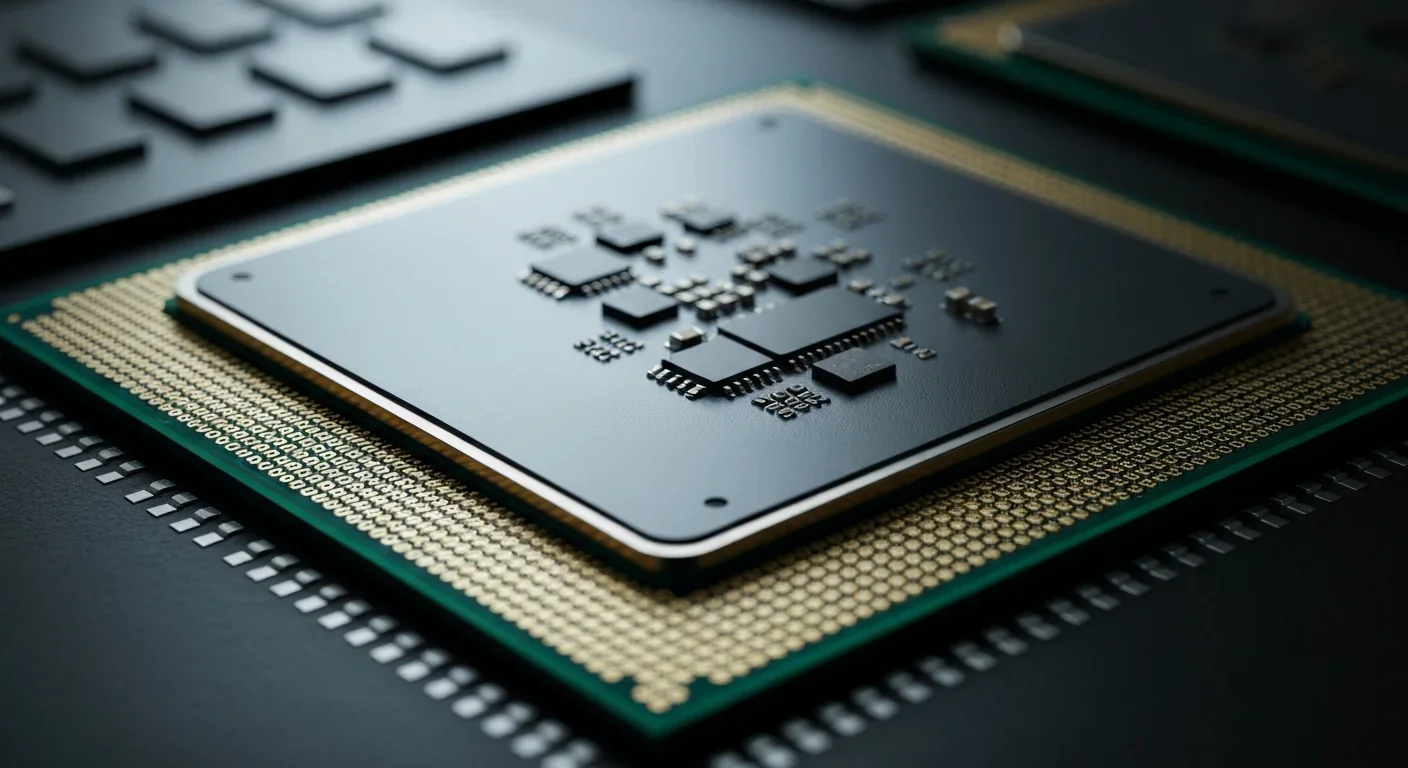

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.