3D-Printed Coral Reefs: Can We Engineer Marine Recovery?

TL;DR: Microalgae capture CO2 40 times more efficiently than trees, transforming industrial emissions into valuable products like biofuels, fish feed, and cosmetics while generating carbon credits and creating profitable climate solutions.

Picture this: a volleyball court-sized installation that cleans the air as effectively as an entire acre of forest. Within the next decade, you'll likely see these algae-powered carbon scrubbers outside factories, refineries, and power plants, transforming the dirtiest industrial emissions into fish food, biofuels, and even cosmetics. What started as a laboratory curiosity is now spreading to industrial sites worldwide, turning pollution into profit and fundamentally changing how we think about carbon capture.

Scientists have unlocked nature's most efficient carbon-eating machine, and it isn't a tree. Microalgae, those microscopic green organisms floating in ponds and oceans, can capture 40 times more CO2 than trees per unit area. That's not a typo. The same photosynthetic process that's been operating for billions of years turns out to be startlingly more powerful when concentrated in controlled environments.

Recent discoveries are accelerating this transformation. Researchers at Harvard's Wyss Institute identified new cyanobacteria strains capable of thriving in high-CO2 environments like factory emissions, growing faster while simultaneously producing valuable biomass. Meanwhile, engineers are developing photobioreactors using nanobubble technology that diffuses CO2 more efficiently than traditional designs, pushing capture rates higher than anyone thought possible just five years ago.

The numbers tell a compelling story. Companies like ALcarbo Technologies report capture rates of 0.54 grams per liter per day, which translates to one volleyball court of photobioreactors matching an entire acre of forest. In Thailand, microalgae systems are already producing biofertilizer, fish feed, and biodiesel while simultaneously sequestering industrial CO2. The technology isn't theoretical anymore, it's operational.

This isn't humanity's first rodeo with revolutionary carbon solutions. The 20th century saw us move from coal to oil to natural gas, each transition promising cleaner energy. Solar panels and wind turbines followed, capturing energy from natural flows rather than ancient deposits. But we've always treated carbon capture as an engineering problem, something to solve with chemicals, filters, and enormous amounts of energy.

Nature took a different approach. For 3.5 billion years, photosynthetic organisms have been pulling CO2 from the atmosphere and converting it into organic matter. Ancient cyanobacteria literally created Earth's oxygen-rich atmosphere through this process. The Great Oxygenation Event, which began around 2.4 billion years ago, transformed our planet's chemistry and made complex life possible. Those same organisms are now poised to help reverse the atmospheric changes we've caused in just two centuries.

The industrial revolution taught us to extract and burn. The green revolution taught us to grow more food on less land. Now we're learning to farm carbon itself, turning the very emissions that threaten our climate into valuable products. History suggests that the most successful environmental technologies are those that align economic incentives with ecological benefits. Algae carbon capture does exactly that.

Past attempts at biological carbon sequestration focused on reforestation and soil carbon. These approaches work, but they require vast amounts of land and decades to show results. Algae-based systems can be installed wherever emissions occur, operate year-round regardless of climate, and produce measurable results within days. The shift from passive sequestration to active biomanufacturing represents a fundamental reimagining of how industrial systems can operate.

Understanding how algae capture carbon requires looking at photosynthesis through an industrial lens. Every photosynthetic cell is a microscopic factory, using sunlight to split water molecules and combine the hydrogen with CO2 to form sugars. The process releases oxygen as a byproduct, the same oxygen we breathe.

Traditional carbon capture relies on chemical absorption, using amine solutions to bind CO2 molecules before storing them underground. This approach requires significant energy input and creates no valuable products. Algae-based systems flip this equation, using free solar energy to convert CO2 into biomass that can be sold for multiple applications.

Modern photobioreactors optimize every variable. Temperature controls keep algae in their ideal growth range. Transparent tubes or panels maximize light exposure. Nutrient feeds provide nitrogen, phosphorus, and trace minerals. Most critically, CO2 delivery systems ensure the algae have constant access to the carbon they need. Advanced designs use nanobubbles, microscopic gas bubbles that dramatically increase the surface area for CO2 absorption, allowing faster growth and higher capture rates than conventional bubble diffusers.

The engineering challenges are considerable but solvable. Maintaining optimal conditions requires monitoring pH, dissolved oxygen, light intensity, and algae density. Contamination from unwanted species can crash a system. Harvesting requires separating tiny cells from large volumes of water, an energy-intensive process. Yet companies are cracking these problems one by one, developing automated systems that operate with minimal human intervention.

Walk through any industrial zone today and you'll see smokestacks, cooling towers, and the unmistakable signs of carbon-intensive processes. Within a decade, that visual landscape will change. Imagine chemical plants ringed with gleaming photobioreactor arrays, their transparent tubes filled with vibrant green algae cultures. Refineries with algae farms integrated directly into emission streams. Data centers using algae to capture the CO2 generated by backup diesel generators.

This transformation extends beyond aesthetics. The European Union's carbon pricing mechanism and similar schemes worldwide are making emissions increasingly expensive. Companies facing carbon taxes suddenly find algae systems economically attractive, not just environmentally responsible. When the captured CO2 can be transformed into products worth hundreds or thousands of dollars per ton, the business case becomes compelling.

Real-world applications are already emerging. In Hong Kong, ALcarbo Technologies supplies algae biomass to fish farms, providing high-protein feed while generating carbon credits. Australian researchers are developing accounting frameworks that allow companies to claim verified carbon reductions from photobioreactor operations. UK startups are producing carbon-negative biofuels, where the algae capture more CO2 during growth than is released when the fuel burns.

The potential extends to unexpected sectors. Construction companies are experimenting with living building materials containing photosynthetic microorganisms, creating structures that actively clean the air around them. Cosmetics manufacturers want algae-derived proteins and oils. Pharmaceutical companies see potential in algae-produced compounds. Each application creates a new revenue stream, making carbon capture profitable rather than merely compliant.

Here's where algae carbon capture gets interesting from a business perspective. Traditional carbon capture and storage (CCS) costs between $50 and $100 per ton of CO2 removed, sometimes much more. That's pure cost, no revenue generation. Companies do it because regulations require it or carbon credits partially offset the expense.

Algae systems change the calculation entirely. The carbon credit market alone values verified CO2 removal at $30 to $100 per ton, depending on the mechanism and market. Puro.earth, a major carbon removal marketplace, recently approved a methodology for microalgae carbon fixation, opening this market to algae producers. Add the value of biomass products and the economics shift dramatically.

Consider the product portfolio. Algae biomass sells for $5 to $10 per kilogram for food-grade applications, $2 to $5 per kilogram for animal feed, and $1 to $3 per kilogram for biofuel feedstock. A system capturing 10 tons of CO2 daily might produce 5 tons of dry biomass, generating $5,000 to $50,000 in product value depending on applications. Meanwhile, it creates 10 tons worth of carbon credits, adding another $300 to $1,000. These aren't abstract projections; they're prices companies are paying today.

The global carbon capture market is projected to reach $11.7 billion by 2030, growing at 17% annually. The algae products market is expanding even faster, driven by demand for sustainable proteins, omega-3 fatty acids, and biofuels. Companies entering this space aren't choosing between environmental responsibility and profitability; they're pursuing both simultaneously.

Investment is flowing accordingly. Startups focused on algae carbon capture raised over $200 million in 2024 alone, with major venture firms and industrial corporations participating. The technology has moved past proof-of-concept to commercial demonstration, and the next phase involves scaling to gigaton impact.

The most obvious benefit is carbon removal, but that's just the beginning. Algae systems offer a rare combination of environmental remediation and economic productivity that few other technologies can match.

Water treatment represents an unexpected advantage. Algae thrive on nitrogen and phosphorus, the same nutrients that cause algal blooms and dead zones when they pollute waterways. Industrial wastewater often contains these nutrients alongside CO2, making it ideal feedstock for photobioreactors. Companies can treat their wastewater, capture their emissions, and produce valuable biomass simultaneously.

Energy security gets a boost too. Unlike fossil fuels that must be extracted from specific locations, algae can grow anywhere with sunlight, water, and CO2. Countries without oil reserves can produce transportation fuels domestically. Remote communities can generate energy from local emissions. The geopolitical implications are profound, potentially reducing resource conflicts and energy dependence.

Food security improves when algae replace soybeans and fishmeal in animal feed. Currently, vast tracts of land grow crops that become livestock feed, driving deforestation and biodiversity loss. Algae can produce equivalent nutrition in photobioreactors occupying a tiny fraction of the land, freeing agricultural space for food crops or ecosystem restoration. The United Nations has identified microalgae as a critical protein source for feeding the planet's growing population sustainably.

Perhaps most intriguingly, algae systems create distributed resilience. Rather than relying on massive, centralized carbon capture facilities, industries can deploy modular photobioreactor arrays at thousands of emission points. This distributed approach reduces transportation costs, enables local production of valuable products, and creates redundancy in carbon removal infrastructure.

Let's be honest about the obstacles. Algae carbon capture faces significant technical, economic, and regulatory hurdles that enthusiastic projections sometimes gloss over.

Scaling remains the primary challenge. A single coal power plant emits millions of tons of CO2 annually. Capturing even 10% of that with algae would require photobioreactor installations covering hundreds of acres and costing hundreds of millions of dollars. Current systems work at pilot scale but haven't demonstrated gigaton-scale potential.

Water usage concerns some critics. While algae systems recycle most of their water, evaporation and biomass harvesting create net consumption. In water-stressed regions, this poses challenges. Coastal installations might use seawater and salt-tolerant species, but inland sites need freshwater sources. Researchers are exploring closed-loop designs that minimize water loss, but these add complexity and cost.

Energy balance calculations matter tremendously. Growing algae is solar-powered, but harvesting, drying, and processing biomass requires energy. If that energy comes from fossil sources, the net carbon benefit shrinks or disappears entirely. Life cycle assessments show positive carbon balances for well-designed systems, but poorly implemented projects can be carbon-neutral or even carbon-positive.

Contamination risks never fully disappear. Photobioreactors are biological systems, vulnerable to invasive species, pathogens, and grazing zooplankton. A contamination event can destroy a culture overnight, requiring weeks to restart. Open pond systems are cheaper but more vulnerable. Closed photobioreactors are more secure but more expensive. There's no perfect solution, only tradeoffs.

Market volatility creates business risk. Carbon credit prices fluctuate with policy changes and market sentiment. Biomass product prices vary with agricultural commodity markets. A company building an algae facility makes a long-term bet on both markets remaining favorable. Policy uncertainty, particularly around carbon pricing mechanisms, makes investors cautious.

Different regions are approaching algae carbon capture with distinct strategies shaped by their resources, regulations, and industrial structures.

Asia leads in commercial deployment, driven by high carbon prices, dense industrial zones, and government support. China views algae technology as strategic for energy security and emissions reduction, investing heavily in research and pilot projects. Hong Kong and Singapore are testing urban applications where space constraints make high-efficiency carbon capture attractive. Japan is exploring algae integration with existing industrial processes, leveraging its expertise in bioprocess engineering.

Europe emphasizes integration with circular economy principles. The EU's Green Deal and carbon border adjustments create strong incentives for on-site carbon capture. Australian researchers focus on certification and accounting, developing frameworks that make algae carbon removal verifiable and tradable in international markets. Scandinavian countries are testing systems in harsh climates, proving that photobioreactors can operate year-round even at high latitudes when properly designed.

North America takes a startup-driven approach. Venture capital is funding dozens of companies exploring different algae species, reactor designs, and business models. Some target commodity markets like biofuels and animal feed. Others focus on high-value products like omega-3s and astaxanthin. The diversity of approaches increases the likelihood that multiple business models will succeed, but it also fragments the industry and slows standardization.

Developing nations see potential for leapfrogging. Just as mobile phones allowed countries to skip landline infrastructure, algae systems might enable emissions-intensive economies to adopt carbon capture without massive capital expenditures on traditional CCS. International climate finance mechanisms increasingly support nature-based solutions, which could include algae projects that combine carbon removal with local economic development.

So what should individuals, companies, and communities do to prepare for this transformation?

For professionals, expertise in bioprocess engineering, photobioreactor design, and carbon accounting will be increasingly valuable. Universities are expanding programs in industrial biotechnology and sustainable manufacturing. If you're early in your career and interested in climate solutions, these fields offer growth opportunities that combine biology, engineering, and environmental science.

Investors should watch the carbon credit markets and algae startup ecosystem. Early-stage companies need capital for demonstration projects, while later-stage firms require funding for commercial deployment. The risk-reward profile is improving as the technology matures. Diversification across multiple companies and approaches makes sense given the uncertainty about which business models will dominate.

Companies with significant CO2 emissions should evaluate algae systems for their facilities. Even if they're not ready for full implementation, pilot projects can provide learning and potentially generate carbon credits under emerging methodologies. Industries with emissions plus water treatment needs (food processing, chemical manufacturing, wastewater treatment) are particularly well-positioned to benefit from integrated systems.

Policy makers can accelerate adoption through targeted incentives. Carbon pricing remains the most powerful tool, but regulations that credit on-site biological carbon capture, streamline permitting for photobioreactor installations, and support research into local algae strains would help. Government procurement of algae-derived products can create stable markets while demonstrating demand for carbon-neutral alternatives.

Communities near industrial facilities might advocate for algae installations as alternatives to traditional carbon capture. Unlike underground CO2 storage, which some communities oppose due to safety concerns, photobioreactors produce visible, tangible products that can support local industries and jobs. They transform emissions from invisible pollution into living systems that improve air quality while generating economic value.

Step back and consider what algae carbon capture represents. We're taking an ancient biological process, optimizing it with modern engineering, and deploying it to address a planetary crisis of our own making. It's simultaneously high-tech and fundamentally natural, industrial and biological, profitable and environmental.

This approach signals a broader shift in how humanity relates to natural systems. For centuries, we've viewed nature as something to dominate or preserve, resources to exploit or wilderness to protect. Algae carbon capture suggests a third path: partnership with biological processes, designing industrial systems that work with photosynthesis rather than against it.

The technology won't solve climate change alone. We still need rapid deployment of renewable energy, electrification of transportation, improved energy efficiency, and protection of existing ecosystems. But algae systems could capture billions of tons of CO2 from sources that are difficult or impossible to eliminate entirely, heavy industry, cement production, chemical manufacturing, and as a bridge while other sectors decarbonize.

Perhaps most importantly, algae carbon capture demonstrates that climate solutions can create value rather than merely imposing costs. Every ton of CO2 captured becomes raw material for products people want. Every photobioreactor installation creates jobs, generates revenue, and proves that environmental technology can be good business. That's a narrative that builds political support and attracts private capital, both essential for deployment at the scale required.

The volleyball court that cleans like an acre of forest is no longer a clever metaphor. It's operating in Hong Kong, being tested in Australia, studied in laboratories worldwide, and planned for industrial sites across multiple continents. Within your lifetime, perhaps within this decade, these living carbon scrubbers will become as common outside factories as smokestacks once were.

The algae are ready. The technology is proven. The economics are improving. The question now is how fast we can scale production to meet the planetary challenge. That's up to the investors, engineers, entrepreneurs, and policy makers reading this. The future of carbon capture isn't just mechanical or chemical; it's alive, photosynthetic, and already growing.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

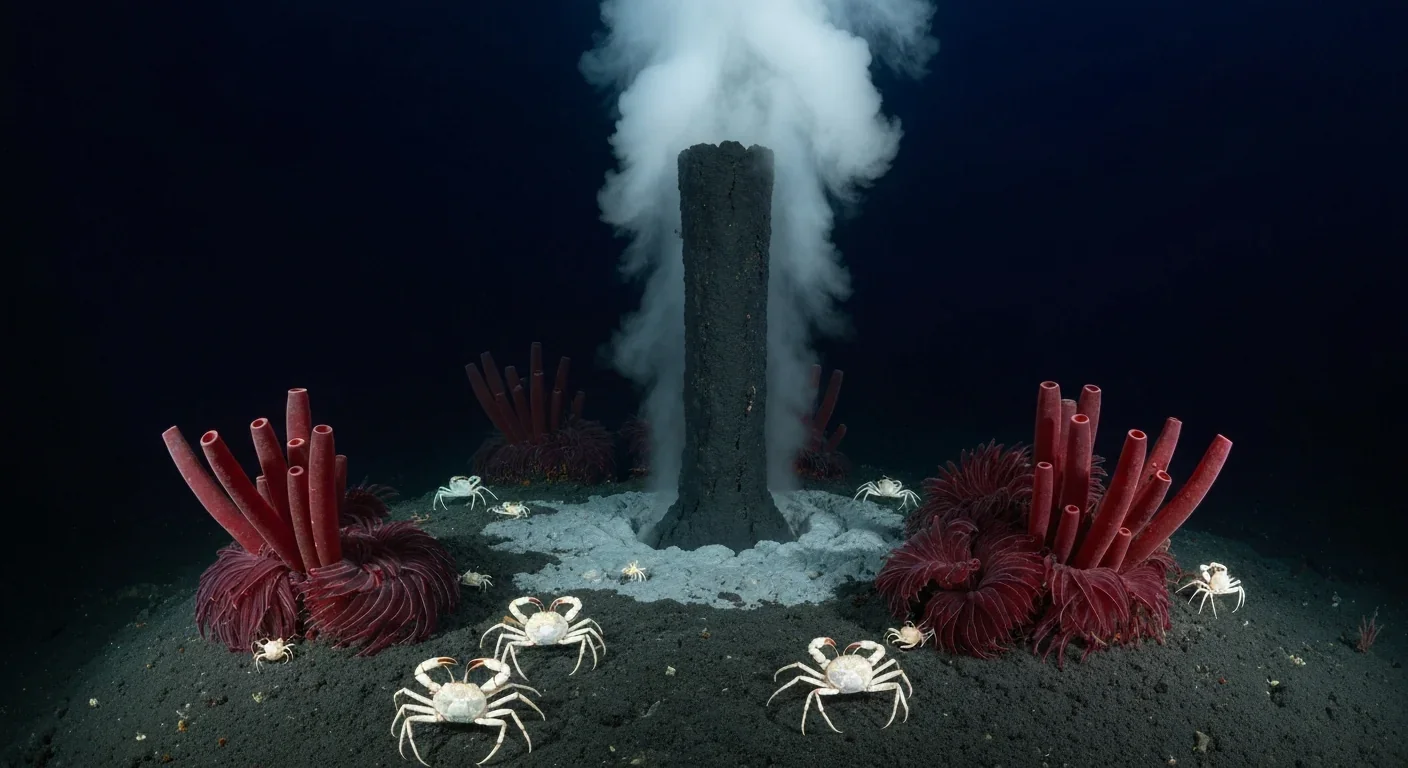

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

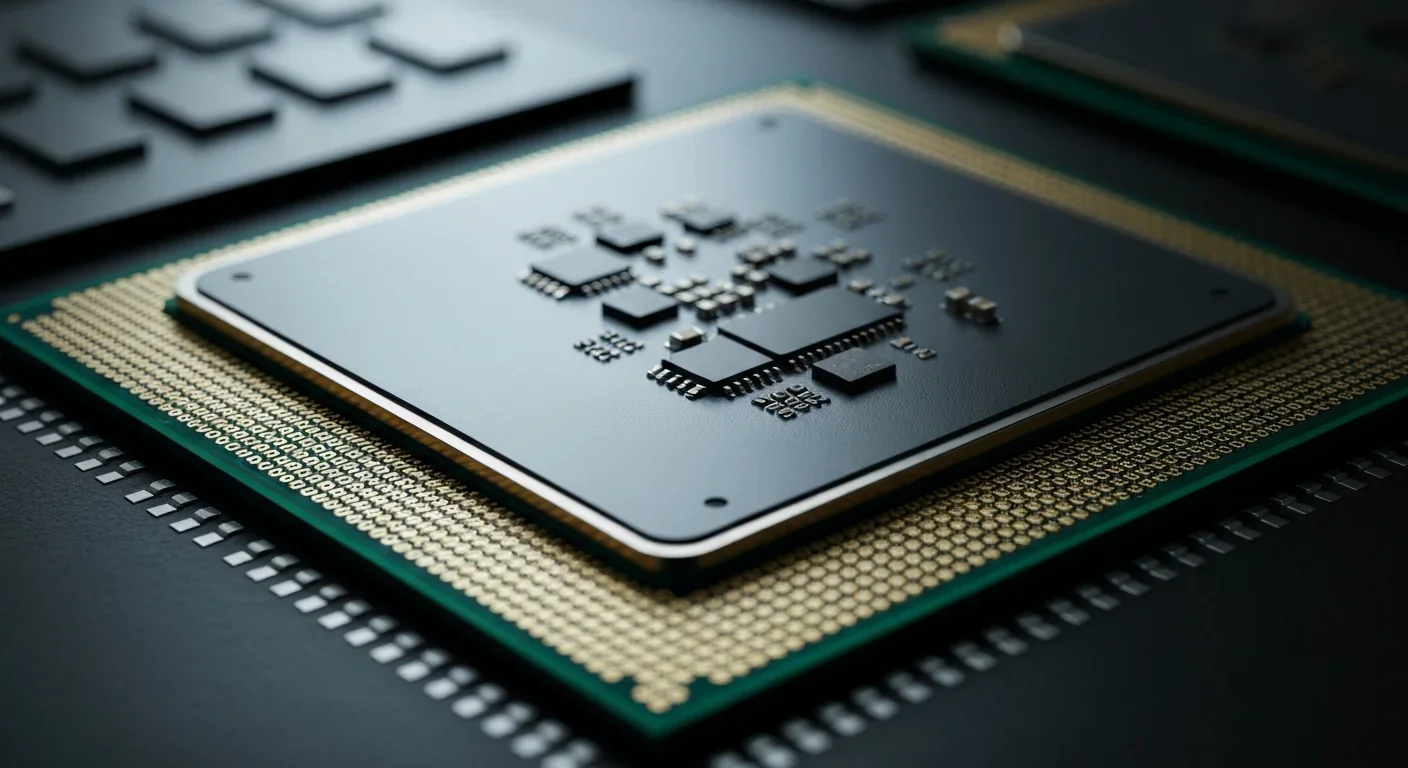

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.