3D-Printed Coral Reefs: Can We Engineer Marine Recovery?

TL;DR: Agricultural hemp waste can be transformed into carbon nanosheets that create supercapacitors charging in seconds rather than hours, at one-thousandth the cost of graphene, potentially revolutionizing electric vehicles and renewable energy storage.

What happens when agricultural waste becomes more valuable than the crop itself? Researchers have discovered that discarded hemp fibers can be transformed into carbon nanosheets that charge electric vehicles in seconds, store renewable energy, and cost a fraction of today's battery technology. This isn't speculation about some distant future. It's happening now, and the implications reach far beyond energy storage.

In 2014, materials scientist Dr. David Mitlin made an unexpected discovery. His team was searching for cheaper alternatives to graphene, the wonder material that promised to revolutionize electronics but remained prohibitively expensive at over $60,000 per gram. The answer came from an unlikely source: the leftover bast fibers from Canada's hemp textile industry, typically burned as waste or used as animal bedding.

What Mitlin found was remarkable. When hemp bast fibers are heated for 24 hours at just over 350°F, then blasted with intense heat, they exfoliate into carbon nanosheets with properties matching or exceeding graphene. "Our device's electrochemical performance is on par with or better than graphene-based devices," Mitlin reported, describing supercapacitors that achieved energy densities of 12 watt-hours per kilogram, two to three times higher than commercial counterparts.

"Our device's electrochemical performance is on par with or better than graphene-based devices."

- Dr. David Mitlin, Materials Scientist

The real shock? These hemp-derived materials could be produced for roughly $500 to $1,000 per ton, making them potentially a thousandth of the price of graphene. Suddenly, high-performance energy storage didn't require exotic materials or complex manufacturing. It just needed agricultural waste and heat.

The transformation from plant fiber to energy storage happens through a surprisingly straightforward process. Hemp bast fibers, the long strands that run through the plant's stem, contain a naturally ordered cellulose structure. When subjected to hydrothermal synthesis and pyrolysis, this structure breaks down in a controlled way.

During hydrothermal treatment, the fibers are heated in a water-rich environment under high pressure. This pre-treatment enhances porosity and uniformity. Then comes pyrolysis, where the material is heated to 700°C or higher without oxygen. The organic compounds burn off, leaving behind pure carbon arranged in nanosheets with extraordinary surface areas exceeding 2,000 square meters per gram.

To put that in perspective, a single gram of this material, if you could unfold it flat, would cover roughly half a basketball court. That enormous surface area is what makes supercapacitors work. Unlike batteries, which store energy through slow chemical reactions, supercapacitors store it electrostatically. Ions in the electrolyte physically move to form an electric double layer on the carbon surface. More surface area means more places for ions to gather, which means more energy storage.

A single gram of hemp-derived carbon nanosheets, if unfolded flat, would cover roughly half a basketball court. This enormous surface area is the key to its superior energy storage capabilities.

The beauty of this approach is its simplicity compared to graphene production, which typically requires chemical vapor deposition, mechanical exfoliation, or other energy-intensive processes. Hemp-derived carbon can be produced in relatively simple batch processes that could scale to industrial levels without exotic equipment or rare materials.

The most transformative aspect of hemp supercapacitors isn't their energy density, it's their charging speed. Lithium-ion batteries charge through chemical reactions that fundamentally take time. Ions must physically migrate through solid materials, reactions must proceed to completion, and heat must be managed to prevent degradation. Even the fastest-charging electric vehicles today still need 15 to 30 minutes for a meaningful charge.

Hemp supercapacitors charge in seconds.

This happens because supercapacitors rely on physical ion movement rather than chemical transformation. When you plug in a hemp supercapacitor, ions in the electrolyte immediately rush to the massive surface area of the carbon nanosheets, forming an electrical double layer. There are no chemical bonds to form or break, no structural changes to the electrode material. Just pure physics, moving at the speed ions can migrate through a liquid.

The implications are staggering. Imagine electric vehicles that refuel as quickly as pumping gas. Renewable energy storage that can instantly absorb power spikes from wind farms. Consumer electronics that top up during a coffee break. The charging bottleneck that has constrained battery-powered devices for decades simply disappears.

Performance data backs up these promises. Hemp supercapacitors have demonstrated power densities up to 200 kilowatts per kilogram, enabling rapid energy delivery. They operate across temperature ranges from -40°C to +80°C, far exceeding the operational window of lithium-ion batteries. And they can endure over 100,000 charge-discharge cycles without significant degradation, compared to roughly 1,000 cycles for typical lithium batteries.

The gap between laboratory breakthrough and commercial reality has killed countless promising technologies. Hemp supercapacitors are starting to cross that chasm, though the path hasn't been smooth.

Bemp Research Corporation, a Texas-based startup, is developing lithium-sulfur batteries that incorporate hemp-derived carbon nanosheets. Their B4C-hemp design uses sulfur and boron instead of the cobalt and nickel found in conventional lithium-ion batteries. Beyond cost savings, this offers a safety advantage. If the battery is punctured, sulfur immediately reacts with lithium to form a protective layer, preventing the thermal runaway that causes battery fires.

Wisconsin Battery Company has taken a different approach, targeting smaller applications first. They're developing hemp-based batteries for hearing aids, where the technology's long lifespan and stable performance could eliminate frequent battery replacements. The company is also exploring electric vehicle applications, though commercial products remain in development.

If punctured, hemp-based lithium-sulfur batteries form a protective layer that prevents the thermal runaway fires that have plagued conventional lithium-ion batteries.

These companies face real challenges. Manufacturing processes need to scale from laboratory batches to industrial production. Supply chains must be established to consistently source and process hemp waste. Most critically, the technology must prove itself reliable across millions of charge cycles in real-world conditions, not just controlled laboratory environments.

Yet the economic incentives are powerful. The global industrial hemp market was valued at $6.26 billion in 2024 and is projected to reach $28.26 billion by 2035, driven partly by demand for sustainable materials. With global hemp fiber production exceeding 200,000 tons annually, there's no shortage of raw material. Much of that production currently generates waste bast fibers that are burned or composted. Turning that waste into high-value battery materials creates a compelling circular economy proposition.

Energy storage today carries a heavy environmental cost. Lithium mining depletes water resources in already-arid regions of South America. Cobalt extraction in the Democratic Republic of Congo has been linked to child labor and environmental destruction. The energy-intensive processes required to refine these materials, manufacture batteries, and eventually recycle or dispose of them create a substantial carbon footprint.

Hemp-based supercapacitors offer a different equation. The feedstock is agricultural waste that would otherwise be burned or left to decompose. Growing hemp itself is relatively sustainable; the plant requires minimal pesticides and fertilizers, grows quickly, and can even improve soil health through phytoremediation.

The manufacturing process, while requiring significant heat, is simpler than lithium-ion battery production. No rare earth mining, no complex chemical processing, no toxic byproducts requiring careful disposal. At end of life, the carbon material can potentially be reprocessed or safely composted, unlike lithium batteries which require specialized recycling facilities.

This doesn't mean hemp supercapacitors are perfectly green. The pyrolysis process consumes energy, ideally from renewable sources to maximize environmental benefits. Large-scale hemp cultivation would require agricultural land, water, and farming infrastructure. And like all energy technologies, the full lifecycle impacts need rigorous assessment as the industry scales.

"Hemp is forging a link between agricultural waste and cutting-edge energy storage, turning a once-banned crop into a potential cornerstone of sustainable tech."

- Industry Analysis, MyCannabis.com

But the environmental comparison favors hemp. A 2024 study found that hemp-derived carbon cathodes for aqueous zinc-ion hybrid supercapacitors achieved energy densities of 65 watt-hours per kilogram with 98% capacity retention after 2,000 cycles. These devices use zinc instead of lithium, abundant water-based electrolytes instead of toxic organic solvents, and renewable hemp carbon instead of mined graphite.

Hemp's history as a controlled substance casts a long shadow over its technological applications. In the United States, hemp cultivation was effectively banned for decades due to its association with marijuana, despite hemp containing negligible amounts of THC. The 2018 Farm Bill legalized hemp cultivation nationwide, but regulatory frameworks remain complex and vary by state.

For companies developing hemp-based energy storage, these regulations create practical challenges. Sourcing consistent, high-quality hemp waste requires relationships with farmers and processors navigating evolving agricultural regulations. Transporting hemp across state lines can trigger legal complications. International trade faces additional barriers, as hemp regulations differ dramatically between countries.

These regulatory hurdles are gradually diminishing as hemp's industrial applications become more widely accepted. Several countries, including Canada and much of Europe, have embraced industrial hemp production. As the energy storage applications prove their value, regulatory clarity is likely to improve.

Perhaps more significantly, the regulatory landscape around energy storage itself is evolving. Governments worldwide are setting aggressive targets for renewable energy adoption and electric vehicle deployment. These goals require massive improvements in energy storage technology. Hemp supercapacitors, with their sustainable credentials and performance advantages, align well with policy priorities around both renewable energy and circular economy initiatives.

The transition from laboratory curiosity to everyday technology follows a predictable pattern. Early adoption happens in niche applications where the technology's advantages clearly outweigh its limitations. Success in these niches builds confidence, refines manufacturing, and drives down costs. Eventually, the technology becomes economically competitive for mainstream applications.

Hemp supercapacitors are somewhere in the middle of this journey. Within five years, you're likely to see them in specialized applications: emergency power systems that need instant charging, regenerative braking systems in vehicles, power tools that recharge in seconds rather than hours. The first products will cost more than conventional batteries but offer compelling advantages for specific use cases.

The real transformation happens when costs drop enough for mass-market adoption. Electric vehicles with hemp supercapacitors could refuel as quickly as gasoline cars, eliminating range anxiety and charging infrastructure concerns. Home energy storage systems could capture solar power during the day and release it instantly during peak demand, stabilizing the grid and reducing reliance on fossil fuel power plants. Portable electronics could last for years without battery degradation, reducing electronic waste.

This isn't guaranteed. Lithium-ion technology continues improving, and other alternatives like solid-state batteries are also in development. Hemp supercapacitors will need to prove they can deliver on their promise at scale, in real-world conditions, at competitive costs.

But the fundamentals are promising. The raw materials are abundant and renewable. The manufacturing process is relatively simple. The performance characteristics address real limitations of current battery technology. And the environmental benefits align with urgent global priorities.

Perhaps the most intriguing aspect of hemp supercapacitors isn't the technology itself, but what it represents: a different approach to industrial development where waste becomes a resource, agriculture feeds advanced technology, and environmental sustainability enhances rather than constrains economic value.

For farmers, hemp offers a rotation crop that improves soil while generating multiple revenue streams. The seeds produce oil for food and cosmetics. The flowers contain CBD for wellness products. The fibers go into textiles, construction materials, and increasingly, energy storage. What was once burned or composted becomes a high-value industrial material.

For manufacturers, this creates a domestic, renewable supply chain less vulnerable to geopolitical disruptions than rare earth mining. The U.S. reopening of hemp cultivation under federal law allows local growers to supply bast fibers for energy applications, reducing dependence on foreign mineral extraction.

For consumers, it promises better-performing products with smaller environmental footprints. Devices that charge faster, last longer, and don't contribute to toxic waste when discarded. Energy storage that makes renewable power more practical and reliable.

The vision extends beyond hemp. If agricultural waste can become high-performance energy storage, what other waste streams might be transformed into valuable materials? Researchers are already exploring similar approaches with other plant fibers, food waste, and industrial byproducts. Hemp supercapacitors might be less important as a specific technology than as proof of concept for a new industrial paradigm.

The next decade will determine whether hemp supercapacitors fulfill their promise or join the long list of technologies that looked revolutionary in the lab but stumbled in the marketplace. Several factors will prove decisive.

Manufacturing must scale successfully. Laboratory processes that work with gram quantities need to reliably produce tons of consistent, high-quality material. Companies like Wisconsin Battery Company and Alternet Systems are working to bridge this gap, but it's where many promising technologies have failed.

Performance must be validated in real-world applications. The 100,000 charge cycles demonstrated in labs need to translate to years of reliable operation in vehicles, grid storage, and consumer devices experiencing temperature swings, vibration, and abuse.

Economics must reach competitive parity. Even with raw materials costing a thousandth the price of graphene, total system costs include manufacturing, testing, integration, and supply chain infrastructure. Hemp supercapacitors need to match or beat lithium-ion on total cost of ownership, factoring in their longer lifespan and faster charging.

Infrastructure must adapt. Electric vehicles with seconds-long charging need electrical distribution systems capable of delivering massive power bursts. Grid storage requires integration with existing utility infrastructure. These aren't insurmountable challenges, but they require coordination across industries and regulatory environments.

Perhaps most importantly, the technology needs champions. Lithium-ion batteries succeeded partly because major corporations bet their futures on the technology. Tesla's gigafactories, the smartphone industry's massive battery demand, and government incentives for electric vehicles created a virtuous cycle of improvement and cost reduction. Hemp supercapacitors need similar momentum.

Early signs are encouraging. The technology addresses genuine limitations of current batteries. The environmental benefits align with global priorities. The economics are compelling if scale can be achieved. And the raw materials are abundant and renewable.

What started as a curious discovery about agricultural waste has revealed a potential path toward faster, cheaper, more sustainable energy storage. Whether that potential becomes reality depends on the next few years of development, investment, and market validation. But the science is sound, the need is urgent, and the materials are literally growing in fields around the world.

The weeds might just power our future after all.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

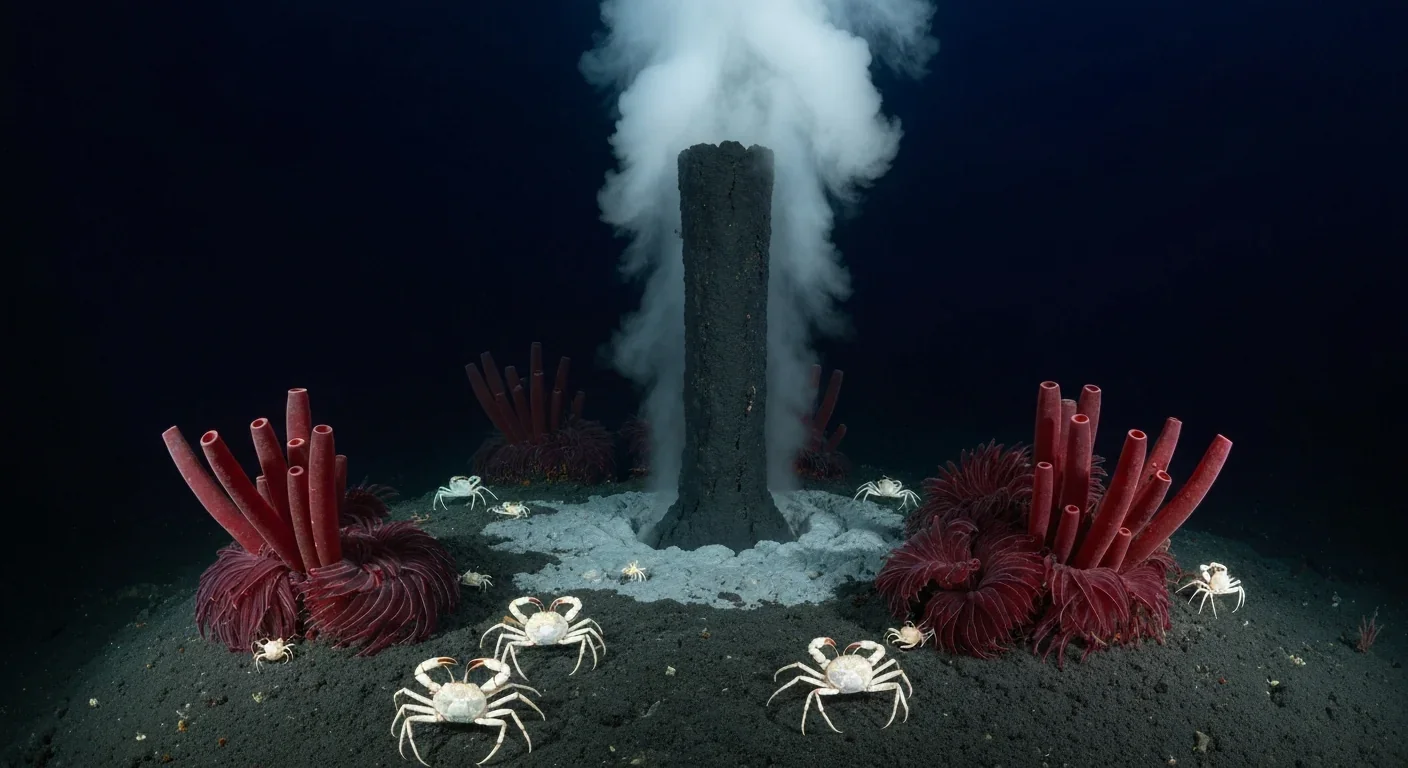

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

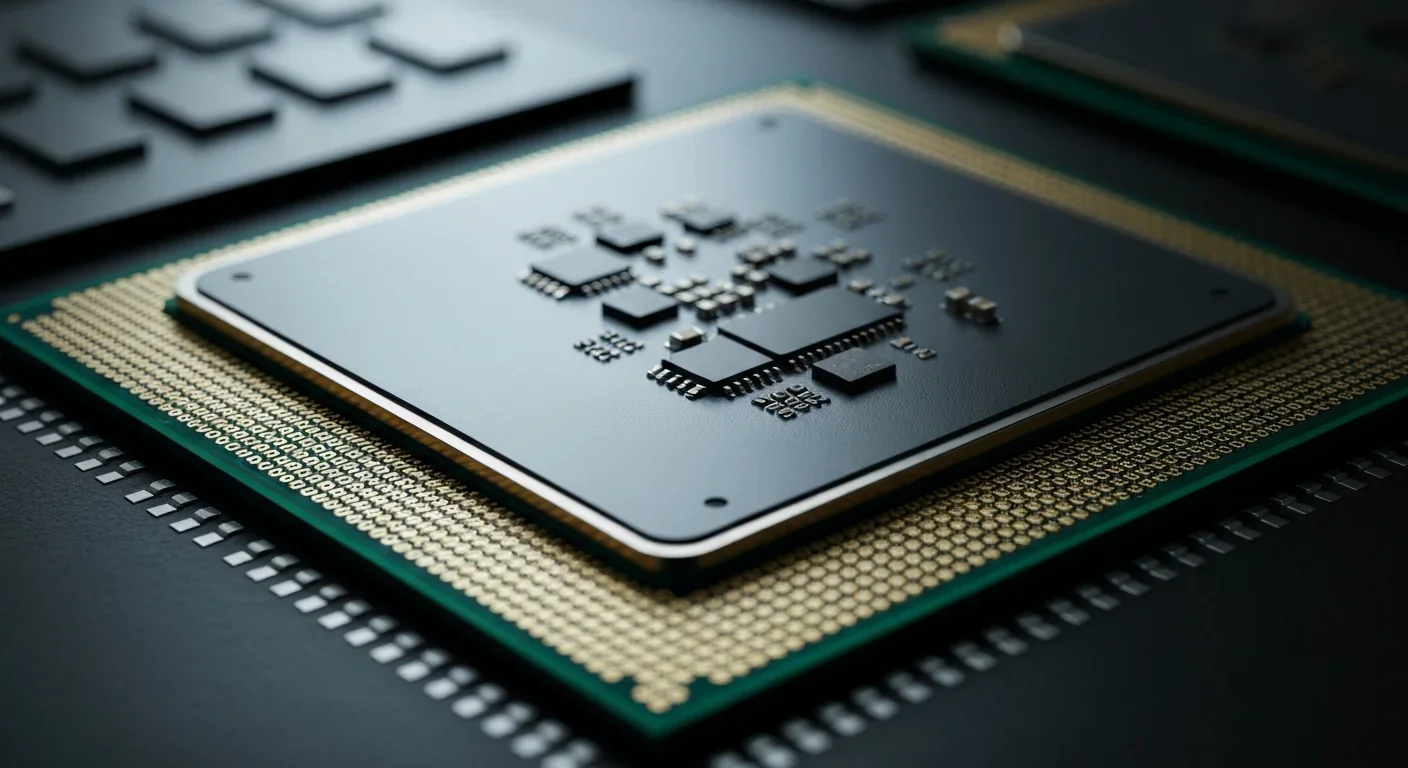

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.