3D-Printed Coral Reefs: Can We Engineer Marine Recovery?

TL;DR: Scientists are transforming CO2, water, and renewable electricity into synthetic diesel fuel through electrochemical conversion. While current costs are double those of fossil fuels, pilot plants in Chile and Germany are proving the technology works at scale, with production costs expected to drop dramatically as the industry grows.

Within the next decade, you'll likely pump fuel into your car that was literally made from thin air. Not metaphorically, but chemically pulled from CO2 in the atmosphere, split from water molecules, and synthesized using renewable electricity. This isn't science fiction waiting to happen. It's happening right now in pilot plants from Chile to Germany, where scientists are flipping the script on climate change by turning our biggest pollution problem into the solution.

Scientists have cracked a puzzle that's haunted chemists for decades: how to efficiently reverse combustion. When you burn fuel, you release CO2 and water. What if you could run that process backward, using renewable electricity to stitch those waste products back into usable fuel? That's exactly what electro-biodiesel production accomplishes through electrochemical conversion.

The breakthrough came when researchers realized they didn't need to perfectly mimic photosynthesis. Instead, they could use electricity to drive chemical reactions that nature never invented. By applying voltage to special catalysts, they force CO2 molecules to accept electrons and combine with hydrogen atoms split from water. The result? Long-chain hydrocarbons identical to diesel fuel, but with a carbon footprint that's net-zero or even negative.

Washington University engineers recently demonstrated an electro-biodiesel process that's significantly more efficient than traditional biodiesel production from crops. Their system converts electricity to fuel at rates approaching 45%, compared to the roughly 1% efficiency of growing plants for biofuel. That ten-fold improvement changes the economics entirely, because you're not competing with food production for farmland, and you're not limited by growing seasons or weather.

The chemistry works like this: renewable electricity powers electrolyzers that split water into hydrogen and oxygen. Separately, direct air capture systems or industrial exhaust streams provide concentrated CO2. These ingredients meet at a reactor where catalysts facilitate their combination into synthesis gas, a mixture of hydrogen and carbon monoxide. Finally, the Fischer-Tropsch process assembles these simple molecules into the complex hydrocarbons that make up diesel fuel.

What makes this a true breakthrough isn't just the science but the timing. Renewable electricity has become cheap enough that using it to make fuel is economically plausible. Solar and wind farms now generate power at costs below $30 per megawatt-hour in ideal locations, making the electricity input for synthetic fuel competitive with the cost of extracting and refining petroleum.

This moment echoes previous energy transitions, but with a crucial difference. When coal replaced wood in the 1800s, it was because coal was better: more energy-dense, easier to transport, and abundant. When oil replaced coal in the 1900s, the same logic applied. But electro-biodiesel isn't necessarily better than petroleum as a fuel; it's better as a system.

The history of energy is the history of finding increasingly concentrated forms of stored sunlight. Wood is sunlight from recent decades, coal from ancient forests, oil from prehistoric algae. Each transition took us deeper into the past to harvest more ancient sunshine. Electro-biodiesel reverses that trajectory. Instead of mining the past, we're manufacturing the present, capturing today's sunlight with solar panels and today's carbon with capture systems.

Previous energy transitions happened because someone discovered a resource and built an industry to exploit it. This transition is different because we're deliberately engineering it to solve a problem, not just to maximize profit. That changes the dynamics entirely. Pennsylvania didn't develop oil fields to save the whales from lamp oil harvesting, even though that was the effect. We're developing electro-biodiesel specifically to eliminate carbon emissions.

The parallel to the early oil industry is striking, though. In 1870, Standard Oil's operations looked nothing like ExxonMobil today. The first oil wells were primitive, inefficient, and expensive. Critics reasonably questioned whether petroleum could ever compete with coal. But decades of engineering refinement, economies of scale, and infrastructure development transformed oil into the dominant energy source. Electro-biodiesel pilot plants are at that same primitive stage now, producing thousands of gallons where we need billions.

History also teaches us about unexpected consequences. The automobile was initially promoted as an environmental solution to the horse manure crisis in cities. Nobody predicted traffic jams, suburban sprawl, or climate change. What are the second and third-order effects of abundant synthetic fuel? If we can make unlimited diesel from air and sunshine, do we lose the incentive to electrify transportation? Does cheap synthetic fuel save the internal combustion engine just when we thought we'd phase it out?

Creating fuel from electricity, water, and CO2 requires orchestrating three distinct processes, each with its own engineering challenges. First comes hydrogen production through electrolysis. Modern electrolyzers achieve 70-80% efficiency converting electricity to hydrogen, but they're expensive and sensitive to power fluctuations. Since renewable electricity is intermittent, you either need massive battery storage or electrolyzers that can handle being turned on and off constantly.

Second is carbon capture. While some pilot plants tap into industrial CO2 streams from breweries or cement plants, truly scalable electro-biodiesel requires direct air capture technology that can pull CO2 from the atmosphere. Current systems consume significant energy - about 1.5-2.0 megawatt-hours per ton of CO2 captured. That energy requirement adds to the overall electricity budget for synthetic fuel production.

The third process, synthesizing hydrogen and CO2 into liquid fuels, relies on catalysts and reactions developed decades ago but now optimized for renewable inputs. The Fischer-Tropsch synthesis was invented in 1920s Germany and used by the Nazis to make synthetic fuel from coal during World War II. Modern versions use renewable hydrogen instead, but the fundamental chemistry remains similar: controlling temperature, pressure, and catalyst composition to yield the desired mix of hydrocarbon chain lengths.

Porsche's Haru Oni plant in Chile demonstrates how these pieces fit together in the real world. Located in Patagonia where wind power is abundant and cheap, the facility produced 34,340 gallons of e-fuel in 2023. That's barely enough to fill a few tanker trucks, but it proves the concept works at industrial scale. The plan calls for expanding to 146,000 gallons by 2025 and eventually to 550,000 cubic meters annually, enough to keep Porsche's sports car fleet running on carbon-neutral fuel.

Germany's Kopernikus P2X project takes a different approach, integrating electro-biodiesel production directly with industrial CO2 sources. The Karlsruhe Institute of Technology and Sunfire company are perfecting modular systems that could be deployed anywhere there's renewable electricity and captured carbon. Their goal is to drive production costs below €1 per liter, the threshold where synthetic diesel becomes competitive with fossil diesel in Europe's taxed fuel market.

The engineering isn't just about chemistry. It's about system integration, matching intermittent renewable electricity with continuous chemical processes, managing heat flows, and designing plants that can scale from pilot to commercial production. Every component exists and works, but orchestrating them into an economically viable system remains the challenge.

If electro-biodiesel succeeds at scale, the geopolitical map redraws itself. Countries that currently depend on oil imports could become fuel self-sufficient using only domestic renewable electricity and atmospheric CO2. Oil-exporting nations would see their primary revenue source evaporate, though those with abundant solar and wind resources, like Saudi Arabia and the UAE, are already positioning themselves as future exporters of synthetic fuels instead of crude oil.

The transformation goes deeper than agriculture. Agriculture could change dramatically because we'd no longer need to dedicate farmland to growing fuel crops. Currently, about 4% of global cropland produces biofuels, competing with food production and driving up prices. Electro-biodiesel made in industrial facilities frees that land for food, forest restoration, or other uses.

Transportation infrastructure wouldn't need to change at all, which is both the technology's greatest strength and potential weakness. Existing pipelines, trucks, storage tanks, and vehicles all work perfectly with synthetic diesel because it's chemically identical to petroleum diesel. Airlines are particularly interested because aviation biofuel alternatives that work in jet engines are limited. Batteries are too heavy for long-haul flights, and hydrogen presents storage challenges. Synthetic jet fuel is a drop-in solution.

But that compatibility creates a risk: if synthetic fuels become cheap enough, society might choose to keep burning hydrocarbons in engines rather than electrifying everything. Some environmentalists worry that electro-biodiesel extends the life of fossil fuel infrastructure just when we should be abandoning it. Others counter that we need every tool available, and synthetic fuels solve problems that batteries can't, particularly for aviation, shipping, and remote applications.

The social implications extend to employment. Oil field workers, refinery operators, and gas station attendants might keep their jobs, just producing and selling different fuel. Or the industry might consolidate around large-scale synthetic fuel plants employing fewer people with different skills. The distributed nature of renewable electricity suggests we could see fuel production decentralize, with regions making their own diesel from local solar and wind rather than importing oil from halfway around the world.

Cost is everything, and right now, electro-biodiesel is expensive. Current production costs range from €0.70 to €1.30 per liter ($3-5.50 per gallon), depending on electricity prices and facility location. That's roughly double the retail price of fossil diesel in most markets, and three to four times the wholesale cost.

But costs are falling along a familiar curve. The first solar panels cost hundreds of dollars per watt; now they cost less than fifty cents. The first lithium batteries cost thousands of dollars per kilowatt-hour; now they're under $100. Electro-biodiesel is starting at the expensive end of that curve, but every doubling of production capacity is expected to reduce costs by 15-20% through learning effects, economies of scale, and process improvements.

The economics improve dramatically in specific niches. Aviation fuel sells for more than diesel, and airlines are required by emerging regulations to use sustainable aviation fuel for an increasing percentage of their operations. They'll pay a premium for synthetic fuel even before it reaches price parity with petroleum. Similarly, Formula 1 racing, maritime shipping companies facing emissions regulations, and industries that can't easily electrify may adopt synthetic fuels while costs are still above fossil fuel prices.

The wildcard in the economic equation is carbon pricing. If governments impose meaningful costs on carbon emissions, fossil fuels become more expensive while carbon-neutral synthetics stay the same price. A carbon tax of $100 per ton of CO2 would add roughly $0.25 per liter to fossil diesel costs, closing much of the price gap. Some European countries already have carbon prices approaching that level.

Capital costs matter too. Building a synthetic fuel plant requires upfront investment of hundreds of millions of dollars, compared to drilling oil wells that start producing revenue within months. But once built, a synthetic fuel facility has a lifespan of 30-40 years with predictable operating costs that don't depend on volatile oil markets. For investors with long time horizons, that stability is valuable even if the returns take years to materialize.

The power-to-liquid market is projected to grow at 21.5% annually through 2034, driven by regulatory mandates, corporate sustainability commitments, and improving economics. That growth rate suggests we'll see synthetic fuel production scale from today's thousands of gallons to billions within a decade, bringing costs down to potentially competitive levels.

Efficiency remains stubborn. Converting electricity to hydrogen, hydrogen to synthesis gas, and synthesis gas to diesel involves losses at every step. Even optimized systems only convert about 40-50% of the input electricity into chemical energy stored in the final fuel. That means you need roughly 2-2.5 units of renewable electricity to replace 1 unit of fossil fuel energy. For comparison, electric vehicles convert about 85-90% of electricity into motion, making them far more efficient if the goal is transportation rather than specifically liquid fuel.

Water consumption could become a constraint in regions where electro-biodiesel makes the most economic sense. Producing one gallon of synthetic diesel through electrolysis and synthesis requires roughly 1.5 gallons of purified water. Desert regions with excellent solar resources often lack water, forcing a choice between importing water, building desalination plants, or locating fuel production elsewhere.

Scaling the technology means scaling the supply chain for rare catalysts and specialized equipment. Current electrolyzers rely on platinum-group metals and other expensive materials that could face supply bottlenecks if demand increases suddenly. Researchers are working on catalyst alternatives, but each change requires years of testing to prove reliability and longevity at industrial scale.

Policy uncertainty creates investment risk. Companies won't build billion-dollar synthetic fuel plants unless they're confident the regulatory environment will support carbon-neutral fuels for decades. If governments change direction, mandate specific technologies, or fail to price carbon emissions, the business case collapses. Some analysts argue for technology-neutral carbon pricing; others advocate for specific mandates for synthetic fuels. The policy debate is ongoing, and investment waits for clarity.

There's also the challenge of co-products. The Fischer-Tropsch synthesis doesn't produce pure diesel; it makes a range of hydrocarbons from short-chain gases to long-chain waxes. Refineries can process this into various fuels, but that requires additional infrastructure and adds cost. Some companies are developing bioelectrochemical reactors that use engineered bacteria to produce more selective outputs, but these biological approaches introduce their own complexity.

The transition to electro-biodiesel won't happen overnight, but you can see the preparations already underway. Porsche isn't investing in Chilean wind farms because they need fuel next year; they're positioning the company for a future where synthetic fuel is standard. Airlines are signing purchase agreements for synthetic jet fuel that won't be delivered until 2028 or 2030, locking in supply and supporting the industry's growth.

For individuals, the shift will be almost invisible. One day you'll notice a pump labeled "e-diesel" at the gas station, probably at a premium price initially. Your vehicle won't care what molecules it's burning, as long as they're the right shape. Fleet operators might switch earlier, especially in regions with carbon pricing or sustainability mandates, because they can factor long-term fuel costs into purchasing decisions more easily than individual consumers.

Skills for the emerging industry combine chemical engineering, renewable energy expertise, and process automation. Universities are beginning to offer coursework in power-to-liquid technologies, and companies are training petroleum engineers to work with synthetic fuel systems. The knowledge transfers well because the output is similar, even if the input is radically different.

Policy will shape the timeline more than technology. If governments create clear long-term mandates for sustainable fuels, investment flows. If they dither or reverse course, the industry stalls. Germany and the EU are leading with regulatory frameworks that require increasing percentages of sustainable aviation fuel. The United States has tax credits for synthetic fuel production, though they're less generous than credits for other renewable technologies.

What should you watch to gauge progress? Track the cost per liter from large-scale facilities, not pilot plants. Watch for major airlines signing purchase agreements beyond token demonstration amounts. Notice when oil companies start building synthetic fuel facilities instead of drilling new wells. Those indicators signal that the economics have shifted from experimental to viable.

The future likely includes a mix of solutions. Electric vehicles for short trips in cities, batteries for personal cars, hydrogen for heavy trucks, and synthetic fuels for aviation, shipping, and applications where energy density matters more than efficiency. Electro-biodiesel isn't the only answer, but it's one of the few that could dramatically reduce emissions from sectors that are hardest to electrify.

We're standing at the beginning of an energy transition as significant as the shift from coal to oil. This time we know it's coming, we understand why it's necessary, and we're choosing to engineer it rather than simply letting it happen to us. Whether that leads to a future of abundant clean fuel or merely extends the hydrocarbon economy with a green veneer depends on choices being made right now in laboratories, boardrooms, and legislative chambers around the world. The science works - now we'll find out if the economics and politics can catch up.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

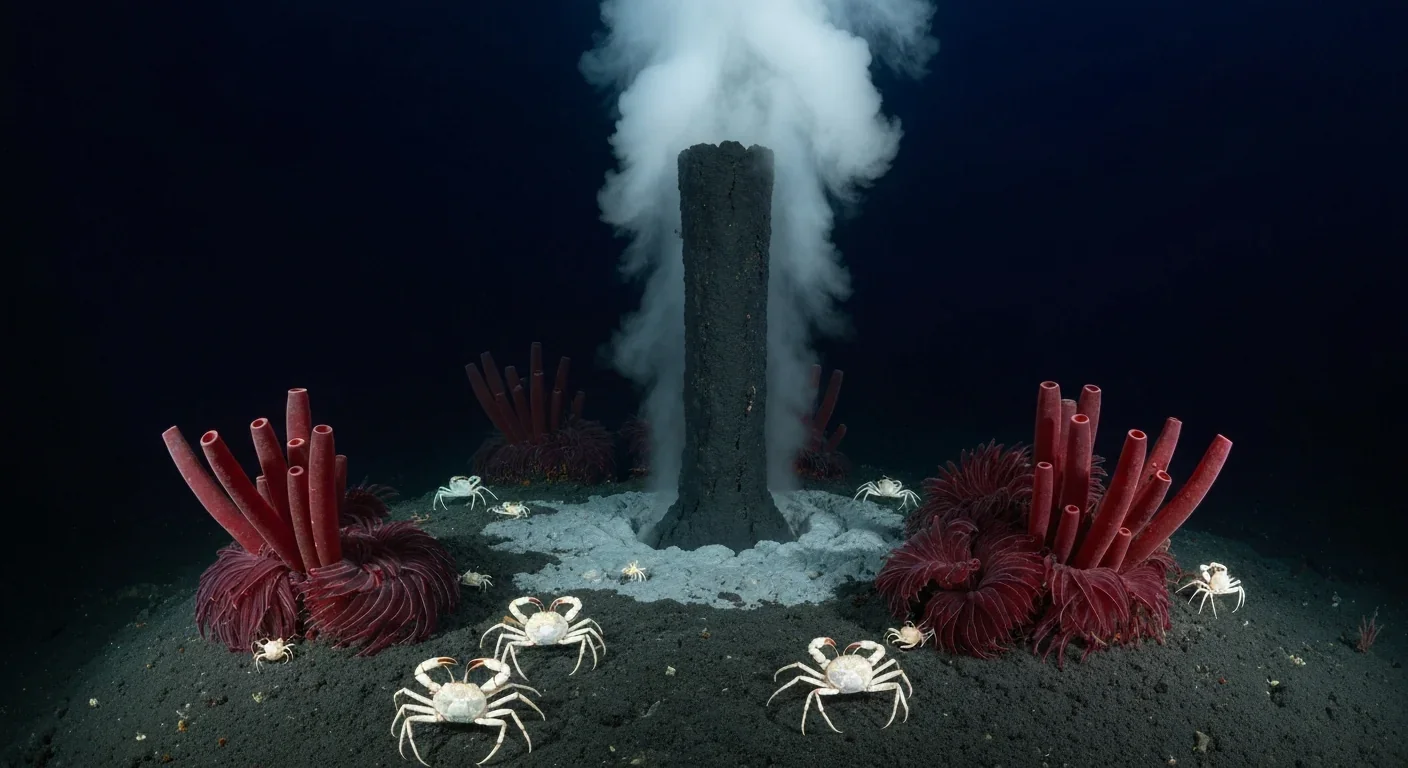

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.