3D-Printed Coral Reefs: Can We Engineer Marine Recovery?

TL;DR: Plastic roads transform waste bottles and bags into durable pavement by mixing recycled plastic with asphalt. India has paved 21,000+ miles, demonstrating potential to address both plastic pollution and infrastructure needs - but microplastic concerns and scaling challenges remain.

By 2030, engineers predict that one in every five roads globally could contain recycled plastic. Right now, discarded bottles, bags, and packaging that would normally choke landfills and oceans are being melted down, mixed with asphalt, and laid as the very roads we drive on. This isn't a far-off dream - India has already paved over 21,000 miles of plastic roads, and cities from Rotterdam to Chennai are proving that trash can literally pave the way to a cleaner future.

The question isn't whether we can turn plastic into roads. We already are. The real question is whether this innovation can scale fast enough to make a dent in our twin crises of plastic pollution and crumbling infrastructure - and whether the roads themselves will hold up over time.

The transformation of plastic waste into road material happens through three main approaches, each with distinct advantages. In the wet process, plastic is melted at around 150°C and dissolved directly into the bitumen binder that holds asphalt together. The dry process takes a different route: pre-processed plastic particles are mixed with dry aggregates before binding. Then there's the modified process, which combines both techniques by pre-blending plastic with binder before mixing with aggregates.

What makes this work? Certain plastics - particularly high-density polyethylene (HDPE) from milk jugs and detergent bottles, and polyethylene terephthalate (PET) from water bottles - have molecular structures that bond surprisingly well with petroleum-based bitumen. When HDPE is added at around 4% of the binder, it increases rutting resistance by up to 50% while maintaining the flexibility roads need for temperature swings.

The process isn't as simple as tossing bottles into a mixing pot. The plastic must be sorted, cleaned, shredded, and processed to specific size ranges. Contamination from food residue or mixed plastic types can wreck the chemistry. Research from Minnesota's transportation department found that the optimal mixing time is just 15 minutes - any longer and the plastic begins to separate from the binder, requiring immediate use rather than storage.

The optimal mixing window for plastic-modified asphalt is just 15 minutes. After that, plastic begins separating from the binder - meaning construction crews must work fast and can't mix batches days in advance.

This constraint reveals a key challenge: plastic roads demand precision logistics. Construction crews can't mix batches days in advance. The material must go from mixer to roadbed within hours, limiting scheduling flexibility but ensuring the plastic stays bonded within the asphalt matrix.

India leads the world in plastic road deployment, driven by necessity as much as innovation. In the late 1990s, Indian chemist Rajagopalan Vasudevan developed a technique that replaces 10% of bitumen with plastic waste, creating what he called "plastic-tar roads." Chennai committed to 1,000 kilometers of plastic roads in 2004. By 2019, India had built over 34,000 kilometers of these roads.

The results have been promising. Roads in Chennai, Pune, and Jamshedpur showed reduced pothole formation and better monsoon resistance compared to conventional asphalt. Field studies in Saudi Arabia and India demonstrated that plastic-modified sections required 20% longer maintenance intervals and showed 30% fewer cracks over five years.

Europe took a different approach with prefabricated plastic roads. In the Netherlands, bicycle paths in Zwolle and Giethoorn were built entirely from recycled plastic using modular, hollow sections that snap together like oversized LEGO bricks. These PlasticRoad modules offer a clever bonus: the hollow interior provides space for utilities like cables, pipes, and sensors, turning the road into infrastructure on multiple levels.

The UK invested £1.6 million in trials across Cumbria, London, Newcastle, and other regions, testing plastic-modified asphalt under British weather conditions. MacRebur, a Scottish company backed by Richard Branson, claims each mile of their roads contains the equivalent of one million plastic bags - a visceral measure of waste diverted from landfills.

"Each mile of Macrebur road contains the equivalent of one million plastic bags."

- Toby McCartney, CEO of Macrebur

Papua New Guinea has been reshaping its roads with recycled plastics, demonstrating that the technology works across diverse climates and economic contexts. From tropical monsoons to European winters, plastic roads have shown they can handle environmental variety.

The critical test for any road material is how it performs under traffic, weather, and time. Laboratory testing of waste plastic film roads showed dynamic stability values between 21,000 and 63,000 cycles per millimeter - dramatically higher than the 3,000 cycles/mm threshold for conventional asphalt. Compressive strength reached approximately 38 MPa, approaching that of cement concrete.

But lab results don't always translate to real-world roads. Field tests on a 1.2m by 6m segment carrying heavy traffic for a month showed that slip resistance met minimum standards for low-speed roads, with British Pendulum Number values of 33-34. This suggests plastic roads work well for side streets, bike paths, and parking areas, but questions remain about their suitability for high-speed highways.

A University of Sunshine Coast study found that MacRebur's plastic asphalt showed superior durability to traditional asphalt in Australian conditions. European pilot studies reported that plastic-modified asphalt reduced annual maintenance costs by approximately 15% over conventional asphalt.

Yet there's a catch. Minnesota researchers found that adding 1.5% plastic by weight reduced cracking resistance in some mixtures. The type of plastic matters enormously: fibers improved concrete strength, while plastic sand decreased compressive strength. This material-specific behavior means one-size-fits-all solutions won't work - engineers must tailor plastic content to local conditions and traffic loads.

Temperature sensitivity adds another layer of complexity. Plastics that improve performance in hot climates might compromise flexibility in cold regions where roads need to handle freeze-thaw cycles without shattering.

The environmental case for plastic roads centers on solving two problems at once: diverting plastic from waste streams and reducing petroleum use in road construction. India's 34,000 kilometers of plastic roads have consumed millions of tons of plastic waste that would otherwise have ended up in landfills or the ocean. The math is straightforward: each kilometer can incorporate roughly one million plastic bags.

By replacing 10-20% of bitumen with plastic, these roads also reduce reliance on petroleum-derived binders. PlasticRoad modules claim 80% lower transport costs, 75% fewer raw materials, and 70% faster construction compared to conventional asphalt - though these are company claims requiring independent verification.

Lifecycle analysis in European pilots suggests plastic roads can be 10-20% cheaper than conventional asphalt in regions with established plastic collection systems, turning waste management costs into construction savings.

But there's an environmental elephant in the room: microplastics. Recent research suggests that plastic asphalt may release microplastics during normal wear and degradation. Every vehicle tire already sheds microplastic particles; adding plastic to the road surface itself raises questions about cumulative environmental impact.

The microplastic question remains unanswered: Do plastic roads release more particles than conventional roads whose tires shed plastic anyway? Long-term monitoring studies are essential before declaring this technology environmentally net-positive.

However, some studies offer reassurance. Laboratory leaching tests showed no harmful substance release after 10,000 rolling cycles. Environmental assessments found that hazardous substances were either not detected or remained below permissible limits in leachates from plastic road materials.

The Penn State Institute of Energy and the Environment is investigating these long-term environmental impacts, recognizing that what sounds good in theory must survive decades of real-world scrutiny.

Cost determines whether innovations scale or stall. India's plastic roads save roughly $670 per kilometer, making them economically attractive for cash-strapped municipalities. But these savings depend entirely on local conditions - particularly the cost of plastic collection and preprocessing.

In regions with established waste management infrastructure and free or cheap plastic waste streams, the economics work beautifully. Coastal cities struggling with landfill capacity and plastic pollution can turn liabilities into assets. But places without robust collection systems face a different equation: the cost of sourcing, sorting, and processing contaminated plastic waste can eliminate any construction savings.

High processing costs and technical complexities pose significant barriers. Food and liquid contamination in waste streams requires extensive cleaning. Mixed plastic types must be separated since different polymers respond differently in asphalt matrices.

There's also the upfront investment challenge. While lifecycle costs may favor plastic roads through reduced maintenance, municipal budgets often prioritize immediate capital expenditure over long-term savings. A road that costs 10% more upfront but lasts 30% longer requires bureaucratic patience and long-term thinking - not always abundant in political cycles.

"The product has to be superior to asphalt on cost, performance, and environmental outcomes to offset those negatives. If it goes horribly wrong, the public will be up in arms."

- Luke Weatherstone, Civil Engineer

This risk aversion extends to regulatory frameworks. Road construction standards were developed for conventional materials over decades of testing. Current civil engineering manuals don't yet accommodate plastic-based pavements, creating a chicken-and-egg problem: regulators want long-term data before approving widespread use, but gathering that data requires large-scale deployment.

We've been here before. In the 1820s, macadam roads - layers of crushed stone compacted together - represented cutting-edge technology that transformed transportation. Engineers who suggested adding petroleum tar as a binder were met with skepticism. Yet by the 1900s, asphalt had become the global standard, paving the way for automobiles and modern logistics.

The concrete revolution followed a similar arc. Early concrete roads in the 1890s suffered from cracking and uneven settling. Critics said concrete would never match the flexibility of asphalt. Today, concrete highways carry millions of vehicles daily, and the two materials coexist based on specific use cases: concrete for heavy loads and longevity, asphalt for flexibility and easier repair.

Each infrastructure shift faced resistance from established industries with sunk costs in existing systems. Asphalt producers had no incentive to champion concrete. The same dynamic plays out now: petroleum-based bitumen has a powerful industry behind it, while plastic road companies remain relatively small players.

But history also teaches that environmental necessity can accelerate adoption. Dutch water management infrastructure evolved not from gradual optimization but from catastrophic floods that demanded innovation. Today's dual crisis - plastic pollution and aging infrastructure - creates similar urgency.

The difference now is speed. Where previous revolutions took decades to spread globally, modern communication and shared climate goals could compress that timeline. India's rapid deployment from 2004 to 2019 shows what's possible when government policy, environmental need, and available technology align.

Scaling plastic roads from pilots to planet-wide deployment faces several technical and logistical hurdles. First, the heterogeneity of plastic waste streams means consistent quality control requires sophisticated sorting. Every batch must meet specific polymer ratios or performance becomes unpredictable.

Second, climate adaptation matters enormously. Plastic-modified asphalt that excels in India's heat might fail in Canada's cold. The optimal plastic type and percentage varies by temperature range, precipitation patterns, and freeze-thaw cycles. This isn't one technology but a family of region-specific formulations.

Third, regulatory standardization must catch up. Without internationally recognized testing protocols and performance standards for plastic roads, each jurisdiction starts from scratch, duplicating trials and delaying approval. Organizations like ASTM International are working to develop standardized testing methods, but the process moves slowly.

The modular PlasticRoad design offers one scalability path: prefabricated sections manufactured in controlled factory conditions, then shipped and installed rapidly. This approach trades construction flexibility for quality control and speed. The hollow interior that accommodates utilities also future-proofs infrastructure, allowing upgrades without tearing up roads.

But can hollow plastic modules handle heavy traffic? Early critics argued that plastic's lighter weight would make such roads "permanently unusable for high-traffic areas." Recent fastening structure innovations that integrate blocks together have reduced settlement and improved load distribution, but the question of highway-grade durability remains open.

The scale of potential impact is staggering. Global road networks span over 64 million kilometers. If even 20% incorporated recycled plastic at the rate of one million bags per kilometer, that would divert roughly 12.8 trillion bags from waste streams - a meaningful dent in the 5 trillion plastic bags produced annually worldwide.

India's approach prioritized rapid deployment using locally available plastic waste, driven by visible environmental crises. Massive plastic accumulation in cities and agricultural areas created political will for immediate action. The result: thousands of kilometers of roads built with lower costs and reduced waste, even if long-term performance data is still being collected.

Europe's strategy emphasizes controlled trials and regulatory validation before scaling. The Dutch bicycle paths serve as monitored test cases, gathering data on wear, microplastic release, and structural performance under real-world conditions. The UK's multi-site trials similarly aim to build evidence before committing to widespread adoption.

This reflects different regulatory philosophies: India's "build and adapt" versus Europe's "test and verify." Neither is inherently superior - contexts differ. India faces immediate plastic waste overwhelming cities, while Europe has established waste management reducing urgency but increasing scrutiny of potential environmental trade-offs.

Developing nations often pioneer waste-to-resource technologies because necessity outweighs caution. Papua New Guinea's adoption shows how smaller economies with limited resources can leapfrog conventional infrastructure by embracing circular economy solutions. Without legacy systems to protect, innovation happens faster.

China's approach - not yet fully documented in Western sources - likely combines elements of both: rapid scaling backed by centralized planning authority, but also substantial R&D investment in optimizing formulations. If China integrates plastic roads into Belt and Road infrastructure projects, that could drive global adoption through sheer scale of deployment.

International cooperation remains limited. Most development happens in national or corporate silos, duplicating effort. A coordinated global research initiative - similar to international collaborations on vaccine development - could accelerate the optimization of plastic road formulations for diverse climates and standardize testing protocols.

The question of equity also arises: will plastic roads become a solution primarily for developing nations while wealthier countries continue using conventional materials? Or will environmental benefits and circular economy principles drive adoption everywhere? The answer likely depends on whether microplastic concerns prove manageable or disqualifying.

Beyond technical and economic hurdles lie deeper questions. If plastic roads become widespread, what happens to recycling markets? Currently, only about 9% of plastic waste gets recycled globally. Most plastic ends up in landfills, incinerators, or the environment. Using plastic in roads doesn't eliminate the need for reducing virgin plastic production - it just delays the waste problem by decades until roads require replacement.

There's also a rebound effect risk: if society views plastic roads as a solution to plastic waste, it might reduce urgency around the harder work of reducing plastic consumption and developing truly circular systems. Roads shouldn't become an excuse for continued overproduction of disposable plastics.

The microplastic question looms largest. While some studies show minimal leaching, others flag concerns about particle release during normal wear. Roads experience constant abrasion from tires, temperature cycling, and chemical exposure. Over a 30-year lifespan, do plastic-modified roads release more, less, or comparable microplastics to conventional roads whose tires shed plastic anyway?

Using plastic in roads doesn't eliminate the need for reducing virgin plastic production - it just delays the waste problem by decades until roads require replacement. Reducing plastic consumption remains paramount.

Systematic monitoring strategies are essential before declaring plastic roads environmentally net-positive. Runoff studies, long-term air quality measurements near plastic roads, and bioaccumulation studies in roadside ecosystems will determine whether we're solving one problem by creating another.

Technical challenges also persist. The 15-minute mixing window and immediate-use requirement limits operational flexibility. Phase separation during storage suggests the plastic-bitumen bond isn't as stable as needed for industrial-scale logistics. Better binder formulations or additives that maintain plastic dispersion could overcome this, but require more research.

Some formulations show reduced cracking resistance, a critical performance metric for longevity. Roads that resist rutting but crack more frequently don't save money long-term. Optimizing the balance between different performance characteristics for each climate zone remains an ongoing challenge.

What do municipalities, engineers, and citizens need to know as this technology matures? First, plastic roads aren't a panacea but a tool suited for specific contexts. They make most sense in regions with high plastic waste generation, warm climates, and lower-speed roads or bike paths.

Cities should invest in waste collection and sorting infrastructure before committing to plastic roads. Without consistent feedstock of clean, sorted plastic, the economics and performance both suffer. Contaminated waste streams undermine the entire value proposition.

Engineers need updated training and standards. Most civil engineering programs still focus entirely on conventional materials. As plastic formulations diversify, professionals must understand polymer chemistry, not just aggregate ratios.

Policymakers should fund long-term monitoring studies that answer outstanding questions about microplastic release, lifecycle emissions, and durability across climate zones. Declaring victory prematurely risks backlash if problems emerge later.

For citizens, plastic roads represent a tangible example of circular economy principles. That bottle you recycle could literally become part of the road you drive on - a concrete (or rather, asphalt) manifestation of waste reduction. But it also highlights that recycling alone won't solve plastic pollution. Reducing consumption remains paramount.

Plastic roads won't save the world. They won't eliminate plastic pollution or solve our infrastructure crisis alone. But they demonstrate that waste and resources aren't inherently different - it's about systems, incentives, and innovation.

The best-case scenario sees plastic roads becoming one tool among many in a broader transition toward circular economies. Combined with reduced plastic production, improved recycling systems, biodegradable alternatives, and better waste management, plastic roads could divert meaningful quantities of waste while creating more durable infrastructure.

The worst-case scenario has plastic roads releasing microplastics at scale, failing to deliver promised durability, and distracting from necessary reductions in plastic production. If regulatory standards weaken to accommodate untested formulations, or if cost pressures lead to shortcuts in waste processing, the technology could do more harm than good.

Most likely, we'll land somewhere in between: plastic roads will find their niche in specific applications and regions where conditions align favorably. India's continued expansion, Europe's cautious validation, and emerging pilots in diverse climates will generate data that clarifies where plastic roads excel and where conventional materials remain superior.

The symbolism matters as much as the substance. Every plastic road built sends a message that waste doesn't have to be destiny, that infrastructure and environmental goals can align, and that circular economy principles can manifest in the very ground beneath our feet.

By 2030, when one in five roads might contain recycled plastic, we'll know whether this revolution fulfilled its promise or taught us expensive lessons. Either way, the road ahead is paved with plastic - and that future is arriving faster than most people realize.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

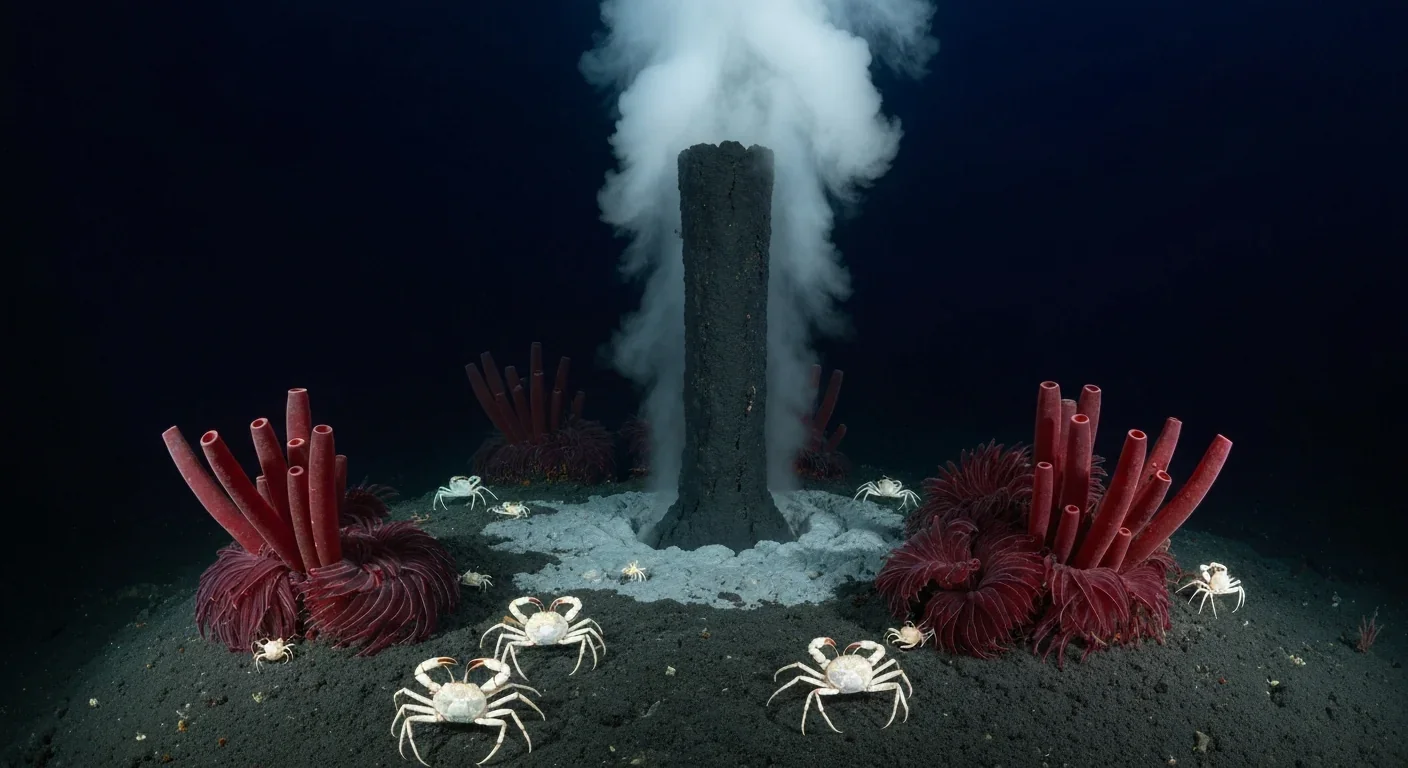

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

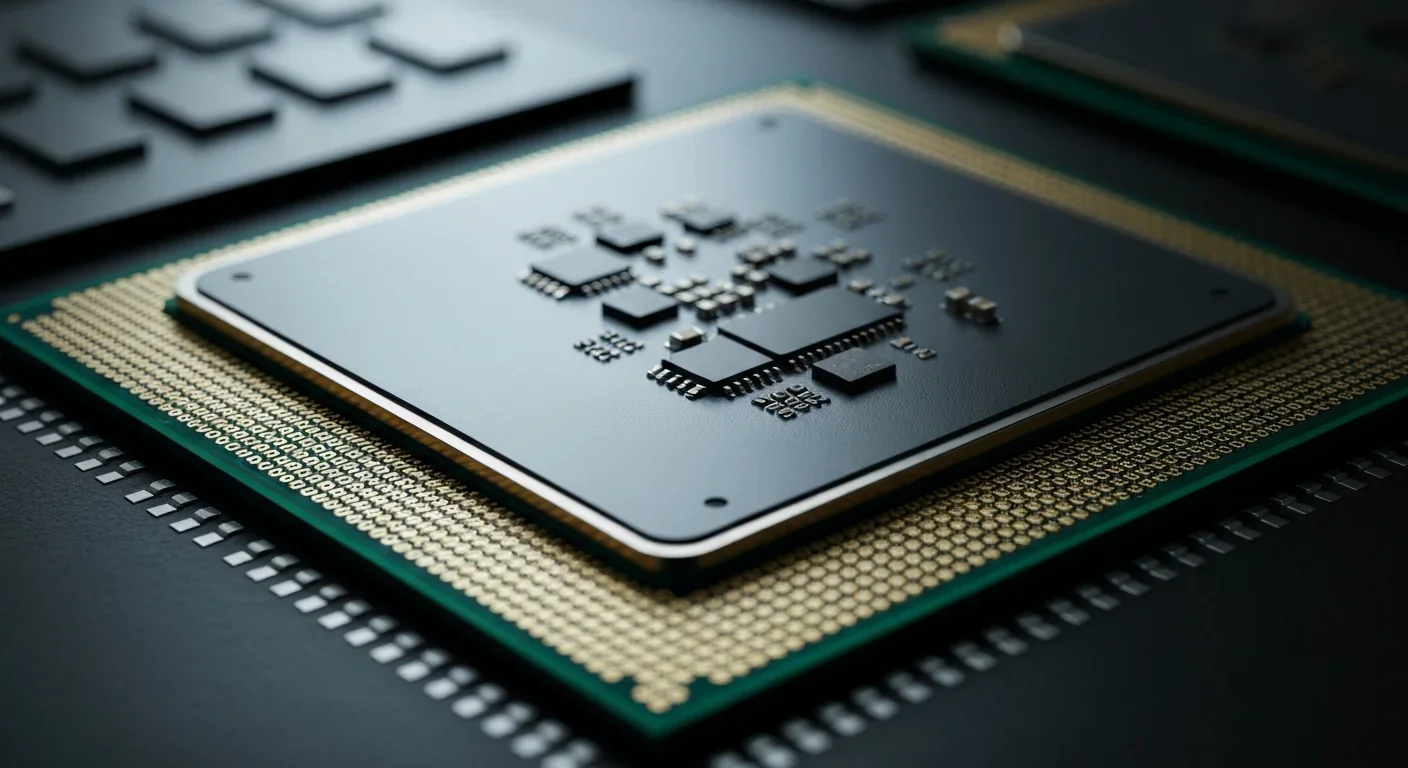

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.