3D-Printed Coral Reefs: Can We Engineer Marine Recovery?

TL;DR: New washing machine filters capture up to 97% of microplastic fibers before they reach oceans, using mechanical, electrostatic, or bio-based technologies that cost $60-200 and require monthly maintenance.

Every time you wash your favorite fleece jacket, up to 700,000 plastic fibers escape into the water system. That's not a typo. A single load of synthetic clothing can release hundreds of thousands of microscopic plastic threads, each one too small to see but collectively massive enough to make laundry wastewater responsible for 35% of all ocean microplastics. But here's the thing nobody talks about: your washing machine probably isn't even trying to stop them.

For decades, we've focused on plastic bottles and shopping bags while ignoring the invisible pollution pouring from our laundry rooms twice a week. Now, a wave of filtration technologies promises to change that, and some are already hitting the market with startling effectiveness. The best systems capture up to 97% of microfibers before they reach municipal water systems, and they do it with hardware you can retrofit onto almost any washing machine in an afternoon.

The microfiber problem starts with what we wear. Polyester, nylon, and acrylic fabrics dominate modern wardrobes because they're cheap, durable, and easy to care for. But durability comes with a dark side. Unlike natural fibers that eventually biodegrade, synthetic textiles break down into ever-smaller fragments that persist in the environment for centuries.

When you agitate synthetic clothing in soapy water at high speeds, friction tears microscopic fibers from fabric surfaces. These particles measure between 1 and 5 millimeters long and less than 1 micron thick. They're so lightweight that they stay suspended in wastewater, flowing through your home's pipes to municipal treatment plants.

Here's where the problem compounds. Most wastewater treatment facilities weren't designed to catch particles this small. While modern plants capture some microfibers in sludge, millions more pass through and empty directly into rivers and oceans. Once in marine environments, these fibers accumulate in sediment, get consumed by fish and shellfish, and work their way up the food chain until they land back on your dinner plate.

Recent studies found that Canadian and U.S. laundry alone releases trillions of microfibers annually. To put that in perspective, if you do two loads of laundry per week, you're contributing roughly 36 million microfibers to the water system each year. Multiply that by every household on the continent, and the scale becomes staggering.

The environmental toll extends beyond ocean pollution. Microplastics have been detected in drinking water, soil, and even Arctic ice. They carry absorbed pollutants like heavy metals and persistent organic chemicals, acting as tiny toxic delivery systems. Marine organisms that ingest microfibers experience reduced feeding, impaired reproduction, and physical damage to digestive systems.

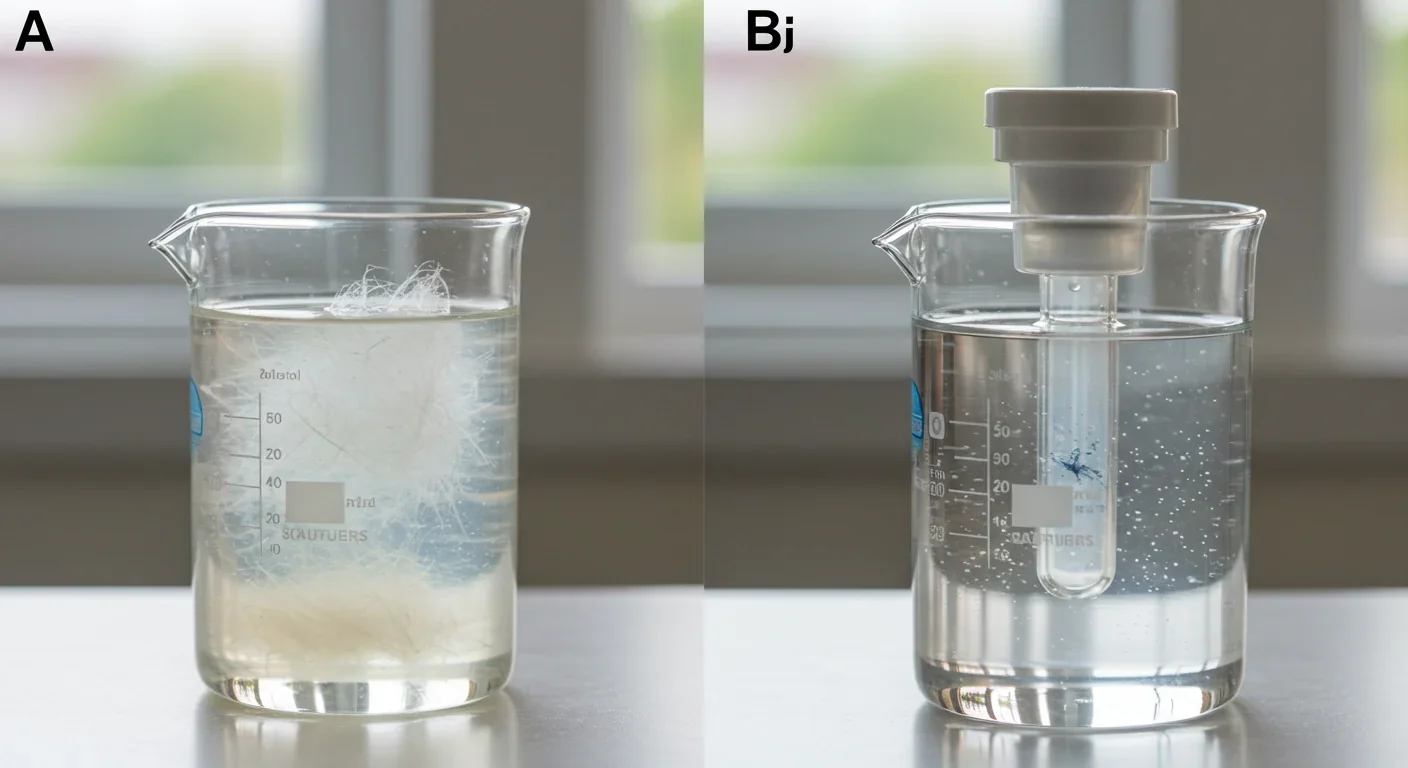

Four distinct approaches have emerged to tackle microfiber pollution at its source, each with different strengths and trade-offs.

Mechanical filtration works exactly like it sounds: water passes through progressively finer mesh screens that physically trap particles. The most sophisticated designs use multi-stage systems with pore sizes ranging from 1,270 microns down to 0.3 microns. Research published in Water journal documented a four-stage mechanical filter achieving 97% microplastic removal across 50 wash cycles.

The key innovation in modern mechanical filters is the use of cyclonic flow. Instead of forcing water straight through a mesh, the filter housing spins the water in a vortex. Heavier particles get flung outward by centrifugal force and drop into a collection chamber, while cleaner water exits through the center. This design prevents clogging and extends the time between cleanings.

Electrostatic filtration takes a different approach. These systems charge fibers that pass through the filter, making them stick to oppositely charged plates or fibers. Think of it like a magnet for plastic particles. Electrostatic filters excel at capturing very fine particles that might slip through mechanical mesh, and they typically offer lower resistance to water flow, which means less strain on your washing machine's pump.

The downside? Electrostatic charge degrades over time, especially when exposed to detergents and fabric softeners. Most electrostatic washing machine filters need cleaning every 1-3 months to restore their capturing ability, and their effectiveness drops faster than mechanical alternatives under heavy use.

Bio-based filters represent the newest frontier. Researchers are developing filters using natural materials like cellulose foam, chitosan derived from shrimp shells, and even modified bacterial cellulose. A recent study demonstrated a foam filter achieving high removal rates in initial testing, with the added benefit of biodegradability at end-of-life.

The appeal of bio-based systems extends beyond environmental optics. Many natural polymers have inherent electrostatic properties that complement their physical filtering structure. They can also be engineered to degrade specific types of plastic or to release enzymes that break down fibers over time. The catch is that most bio-based filters remain in laboratory or pilot stages, with questions about long-term stability and cost-effectiveness still unanswered.

Hybrid systems combine two or more of these approaches. A typical hybrid might use a coarse mechanical pre-filter to catch large particles, an electrostatic middle layer for fine fibers, and a final mechanical stage for polishing. These designs can achieve higher overall removal rates while distributing the filtration burden across multiple mechanisms, potentially extending filter life.

Lab results only tell part of the story. How do these filters perform when real families use them on real laundry over months and years?

Independent testing of three popular aftermarket filters revealed significant variability. The best performer captured 85% of microfibers, while the worst managed only 68%. Effectiveness depended heavily on installation quality, maintenance frequency, and the types of fabrics washed.

One crucial finding: filter performance degrades faster than manufacturers typically advertise. A filter rated for six months often shows measurable decline in capture efficiency after just three months of twice-weekly use. The culprit is usually a combination of fine particle buildup that clogs mesh and chemical residue from detergents that interferes with electrostatic charge.

Field studies in Sri Lanka demonstrated that simple mechanical filters could remove substantial microplastic loads even in developing-world contexts where maintenance might be less rigorous. This suggests that widespread adoption of even basic filtration could make a significant dent in global microfiber pollution.

The four-stage filter tested in Korea showed remarkable consistency. Across 50 complete wash cycles, removal rates stayed between 93% and 99%, demonstrating that well-designed mechanical systems can maintain performance over extended periods. Importantly, the filter also removed 92% of chemical oxygen demand (COD), 89% of suspended solids, and 88% of turbidity, providing benefits beyond just microplastic capture.

Consumer reports paint a mixed picture of real-world satisfaction. Many users praise the environmental benefits but complain about installation challenges, noise from turbulence in filter housings, and the inconvenience of cleaning or replacing filter cartridges. Reddit discussions reveal that some users abandon filters after a few months when the novelty wears off and maintenance becomes a chore.

There's also the question of what to do with captured microfibers. Unlike air filters that can be vacuumed, washing machine filters accumulate wet, soapy plastic sludge. Some systems provide biodegradable collection bags that can be mailed back to the manufacturer for proper disposal, but this adds cost and complexity.

Price tags for washing machine microfiber filters span a wide range. Basic mechanical filters start around $60, while high-end multi-stage systems can exceed $200. Installation is usually straightforward for external filters that attach to drain hoses, but internal filters requiring modifications to the machine's plumbing might need professional installation.

Running costs add up. Replacement filter cartridges typically cost $15-40, and most manufacturers recommend changes every 3-6 months depending on use. If you're doing eight loads per month, annual filter costs could run $60-160 on top of the initial hardware investment.

Compare that to the alternative: letting microfibers flow into municipal water systems. Wastewater treatment plants spend billions upgrading infrastructure to handle challenges they weren't designed for. The cost gets passed to ratepayers through higher water bills. From a societal cost perspective, preventing microfibers at the source is almost certainly cheaper than trying to remove them downstream.

Energy impact deserves consideration. Filters that restrict water flow force washing machine pumps to work harder, potentially increasing electricity consumption. High-density mechanical filters can significantly impact HVAC airflow, and the same principle applies to water systems. Electrostatic and well-designed cyclonic filters minimize this resistance, but buyers should verify that a filter won't void their washing machine warranty or cause premature pump failure.

Maintenance frequency varies by filter type and household laundry volume. Mechanical filters typically need emptying monthly if you wash more than four loads per week. Electrostatic filters require cleaning every 1-3 months to maintain charge. Bio-based filters in current prototypes often need replacement rather than cleaning, which could make them more expensive long-term unless prices drop significantly.

The user experience matters. Reviews highlight that filters with transparent housings, tool-free disassembly, and clear maintenance indicators see better long-term adoption than opaque black-box designs that require wrenches and guesswork about when to clean.

Not all households face the same microfiber challenges. A family that wears mostly cotton and linen generates far fewer synthetic fibers than one with wardrobes full of fleece, athletic wear, and synthetic blankets.

Start by assessing your laundry composition. If more than half your loads contain synthetic fabrics, a mechanical or hybrid filter makes sense. These systems handle high particle loads without performance degradation as long as you maintain them properly. Look for multi-stage designs with the finest mesh your washing machine pump can handle without strain.

If you primarily wash natural fibers with occasional synthetic items, an electrostatic filter might suffice. These lower-resistance designs won't burden your machine's pump, and the reduced particle load means less frequent cleaning.

For renters or anyone who changes washing machines frequently, external filters that attach to drain hoses offer maximum flexibility. You can take them with you when you move, and installation requires no permanent modifications. Several reviewed models simply clamp onto standard drain hoses using adjustable fittings.

Homeowners with older washing machines might consider internal filters that integrate into the machine's existing drain system. These are more complex to install but offer a cleaner aesthetic and often better performance since they can be sized specifically for your machine's flow rate.

Front-loaders and top-loaders have different drainage patterns. Front-loaders pump out in distinct pulses, while top-loaders often drain more continuously. Some filters work better with pulsed flow because it allows particles time to settle between pumping cycles. Check compatibility before buying.

Filters aren't the only answer. Washing clothes less frequently, using colder water, and running shorter cycles all reduce fiber shedding. Research found that garments last longer and release fewer microfibers when washed at lower temperatures with gentler agitation.

Consider specialized laundry bags designed to trap microfibers. These mesh bags hold synthetic garments during washing, catching fibers that break free. While not as effective as machine filters, they capture 50-80% of fibers and work with any washing machine.

Fabric choice matters upstream. Natural fibers like cotton, wool, and linen don't contribute to microplastic pollution. When you do buy synthetics, look for tightly woven fabrics that shed less and avoid cheap fast-fashion items that disintegrate rapidly.

Interestingly, wearing clothes releases more microfibers to the environment than washing them in some studies. Friction from movement, sitting, and contact with other surfaces constantly sheds particles. This means the microfiber problem extends beyond laundry, though washing remains the largest pathway to aquatic environments.

Europe is leading the policy response. France mandated microfiber filters on all new washing machines starting in 2025, the first such law globally. The EU is developing broader regulations on microplastics, including potential restrictions on intentionally added microplastics in products and eventually requirements for washing machine filtration across member states.

New EU regulations will require testing and compliance documentation for products that may release microplastics. This regulatory pressure is driving appliance manufacturers to integrate filtration into new washing machine designs rather than relying on aftermarket accessories.

Several major brands already offer models with built-in microfiber filters. Eco-friendly washing machines increasingly include filtration as a standard feature, though these models typically command premium prices. As regulations tighten and consumer awareness grows, expect filtration to become standard across all price points within the next decade.

Industry consortiums are forming to address the problem collectively. Adidas, Levi's, and Under Armour recently launched a group dedicated to reducing microfiber pollution through textile innovation and washing machine technology. This signals that major apparel companies recognize both the environmental urgency and the potential reputational risk of inaction.

Consumer willingness to pay for microfiber solutions varies significantly by region and demographic. A recent study found that knowledge about microplastic pollution strongly predicts willingness to invest in filtration systems. As awareness spreads, demand for both aftermarket filters and washing machines with built-in filtration is likely to rise, potentially driving prices down through economies of scale.

Next-generation filters are getting smarter. Prototype systems include sensors that monitor filter saturation and send smartphone alerts when cleaning is needed. This addresses one of the biggest adoption barriers: people forget to maintain their filters until performance has already degraded significantly.

Researchers are exploring electrostatic filters that recharge themselves using the kinetic energy of flowing water, eliminating the performance decline that plagues current electrostatic designs. Early results suggest this could combine the low resistance of electrostatic filtration with the long-term stability of mechanical systems.

Bio-based filter materials are advancing rapidly. New formulations using agricultural waste products promise to bring costs down while maintaining biodegradability. If these materials can match the durability of synthetic mesh while decomposing harmlessly at end-of-life, they could solve the "what do we do with used filters" problem.

Some innovators are rethinking the problem entirely. Floating drone systems with water-skimming mechanisms could capture microplastics already in waterways, providing a last line of defense even if household filtration isn't perfect. These downstream solutions won't replace source prevention but could help address legacy pollution.

The most radical proposals involve redesigning washing machines from the ground up with microfiber capture as a core design principle rather than an afterthought. Imagine a machine with multiple filter stages integrated into the water circulation system, real-time particle sensing to adjust cycle parameters, and automated filter cleaning that requires minimal user intervention. Some manufacturers are already testing these concepts.

If you're ready to install a microfiber filter, start by identifying your washing machine's drain configuration. Most modern machines use a standard 1.5-inch drain hose, but verify before ordering a filter to avoid compatibility issues.

Read installation instructions thoroughly before beginning. Many filters work best when mounted vertically with collection chambers at the bottom, which might require creative plumbing in tight laundry spaces. Ensure you can access the filter easily for maintenance; if installation puts the filter behind the machine where you'll never look at it, you probably won't maintain it.

Set a recurring calendar reminder to check and clean your filter. Monthly is a safe interval for most households. Some users tie filter maintenance to other regular chores, like changing HVAC filters or paying monthly bills, to build the habit.

Start with one filter and evaluate performance before investing in systems for every washing machine in your household. Pay attention to how it affects drainage time, whether your machine displays any error codes, and whether you notice any reduction in pump noise or efficiency.

Consider complementary changes like reducing wash frequency, lowering temperatures, and buying fewer synthetic garments. Filters work best as part of a comprehensive strategy, not as a silver bullet.

Microfiber filtration represents a rare opportunity: a technological fix that actually works and scales without requiring massive infrastructure changes. Unlike carbon capture or ocean cleanup megaprojects, washing machine filters are simple, affordable, and can be deployed in millions of households immediately.

The parallels to catalytic converters are striking. When catalytic converters became mandatory on cars in the 1970s, many predicted disaster. Drivers worried about cost and reduced performance. Yet within a decade, the technology became invisible, standard, and hugely effective at reducing air pollution. Washing machine filters could follow the same trajectory.

But technology alone won't solve the microplastic crisis. We also need to address the consumption patterns that create billions of synthetic garments designed to be worn a few times and discarded. We need textile manufacturers to design fabrics that shed fewer fibers. We need retailers to provide clear information about the environmental impact of different materials.

Still, filters are a concrete step you can take today. Every microfiber you capture in your laundry room is one that won't enter the ocean, won't be consumed by marine life, and won't cycle back into the food you eat. When millions of people make that choice, the cumulative impact becomes significant.

The oceans won't clean themselves. But increasingly, your washing machine can do its part.

Ahuna Mons on dwarf planet Ceres is the solar system's only confirmed cryovolcano in the asteroid belt - a mountain made of ice and salt that erupted relatively recently. The discovery reveals that small worlds can retain subsurface oceans and geological activity far longer than expected, expanding the range of potentially habitable environments in our solar system.

Scientists discovered 24-hour protein rhythms in cells without DNA, revealing an ancient timekeeping mechanism that predates gene-based clocks by billions of years and exists across all life.

3D-printed coral reefs are being engineered with precise surface textures, material chemistry, and geometric complexity to optimize coral larvae settlement. While early projects show promise - with some designs achieving 80x higher settlement rates - scalability, cost, and the overriding challenge of climate change remain critical obstacles.

The minimal group paradigm shows humans discriminate based on meaningless group labels - like coin flips or shirt colors - revealing that tribalism is hardwired into our brains. Understanding this automatic bias is the first step toward managing it.

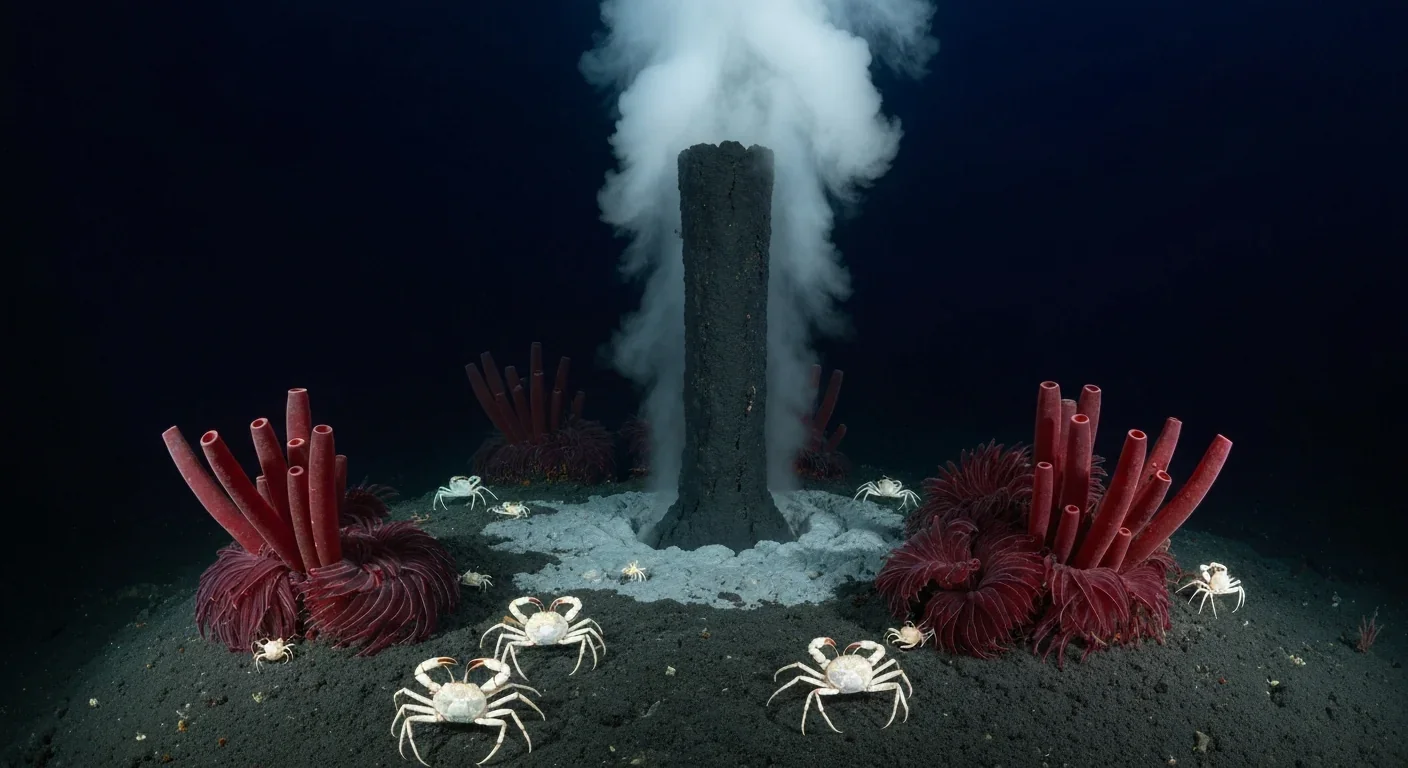

In 1977, scientists discovered thriving ecosystems around underwater volcanic vents powered by chemistry, not sunlight. These alien worlds host bizarre creatures and heat-loving microbes, revolutionizing our understanding of where life can exist on Earth and beyond.

Automated systems in housing - mortgage lending, tenant screening, appraisals, and insurance - systematically discriminate against communities of color by using proxy variables like ZIP codes and credit scores that encode historical racism. While the Fair Housing Act outlawed explicit redlining decades ago, machine learning models trained on biased data reproduce the same patterns at scale. Solutions exist - algorithmic auditing, fairness-aware design, regulatory reform - but require prioritizing equ...

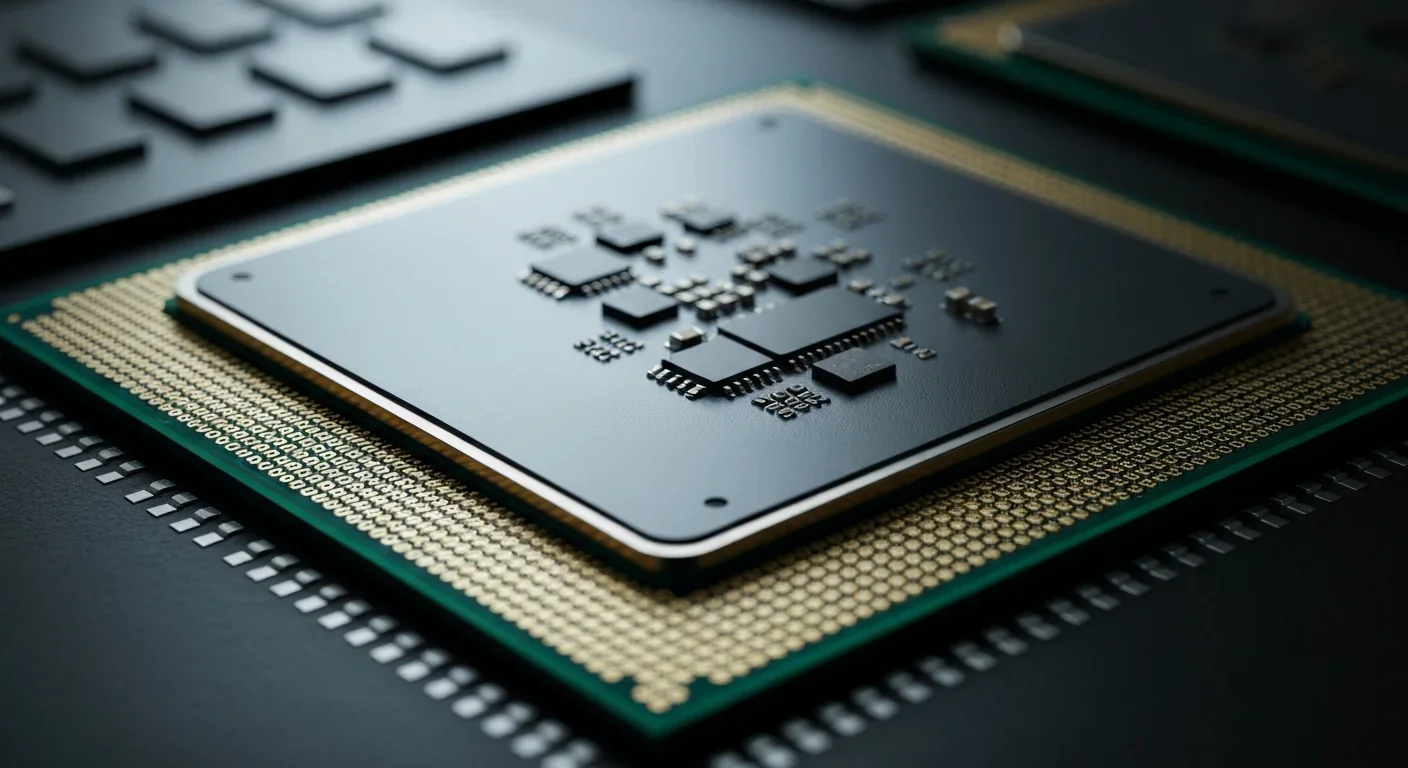

Cache coherence protocols like MESI and MOESI coordinate billions of operations per second to ensure data consistency across multi-core processors. Understanding these invisible hardware mechanisms helps developers write faster parallel code and avoid performance pitfalls.